Satisfying the needs of differential industrial disciplines, flange connections of various types require gaskets to meet the needs of integrity maintenance and efficiency. They are a critical part of the machinery that ensures a gasketable seal between two flange surfaces, thereby preventing any undesired fluid or gas leakage under high pressure and temperature. This blog post will shed light on the importance of gaskets in flange assemblies, discussing their functions, types, material choices, and other important considerations necessary to achieve a high-quality sealing performance. Equipped with this knowledge, the readers are bear great insight into why these small yet mighty objects are central to any industrial application and their contribution to make the system safe and reliable.

Understanding Flanges and Gaskets

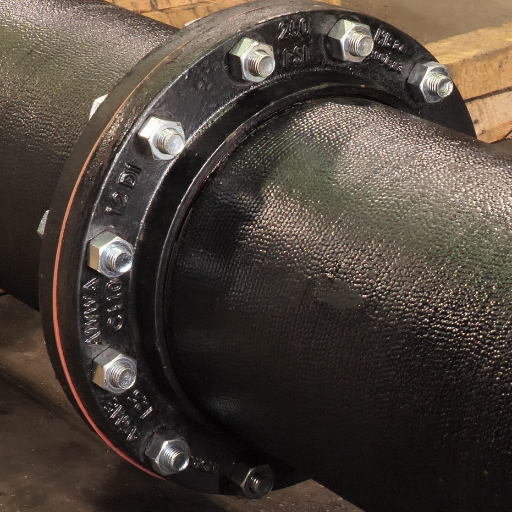

Flanges and gaskets work hand in hand to provide secure and leak-proof connections in piping systems. A flange is a mechanical entity used to connect pipes with valves or other fixtures for enabling ready assembly and disassembly. Gaskets are soft sealing materials that are set between flanges to fill surface irregularities, preventing leakage under different pressure, temperature, and chemical conditions. Such an effective pairing largely depends on the right selection of gasket materials, including considerations around system pressure, temperature, and chemical compatibility. Gasket installation, which requires proper operational practices like ensuring uniform compression and reliable sealing, is also key. Meaning that an incessant balance of perfect design and actual operational precision is required for the realization of the highest performance.

What is a Flange?

A flange is a mechanical entity used to connect pipes, valves, pumps, or other kinds of equipment in a piping system. It serves as a secure point of connection that facilitates assembly, disassembly, and maintenance of the system. A flange is usually circular in shape and is holed for bolts that enable fastening to another flange or a piece of equipment. The flange is designed such that there is provision for a gasket to be fitted in between the sealing surfaces so that a leak-proof connection is ensured under varying operating conditions. They are used predominantly in oil and gas industries and chemical processing, and power generation maintenance; hence instinctively maintain the efficiency or integrity of piping systems.

The Role of Gaskets in Flanges

Gaskets protect surfaces from leakage while bolted flanges are joined together, serving as crucial members in the flange connection assembly. These materials are usually selected depending on the application, temperature, pressure, chemical environment, etc., having a sealing capacity through intimate contact with surfaces to fill microscopic irregularities on the flange face, thereby forming a hard and leak-proof barrier for the safe and efficient conveyance of fluids or gases. While the gasket selection, alignment, and installation are necessary for the integrity of performance and lifespan of flange systems, it becomes all the more pertinent in acute trade areas such as oil and gas, or power generation.

Types of Flanges

Many different types of flanges exist that meet the various demands and requirements of any system act i.e.; weld neck flange being used for high-pressure applications, giving good weld strength; slip-on flange being used for ease of installation and cheaper in cost; socket weld flanges generally applicable for smaller diameter pipelines requiring higher leakage resistance; threaded flange for easy system without welding; blind flange to close piping ends; in addition, lap joint flange is mainly used for applications requiring frequent dismantling, while special flanges such as orifice and reducing flange are essentially design-specific. Choosing a particular type of flange depends upon the criteria of system pressure, temperature, and ease of assembly or maintenance.

Types of Gaskets Used in Flanges

The role of the gaskets is quite critical in ensuring a secured seal, devoid of leaks, between the flanges. The main types of gaskets have been classified into non-metallic, semi-metallic, and metallic gaskets. Non-metallic gaskets, such as rubber, PTFE, or compressed fiber, are mostly used in low-pressure and low-temperature applications to allow for greater flexibility and resilience. Semi-metallic types, like spiral wound or corrugated gaskets, use both metal and non-metal materials and offer an intermediate value of strength and pliability for medium to high-pressure applications. Metallic gaskets including RTJ gasket provide excellent sealing under high-pressure and high-temperature conditions. The selection of a gasket is based on application temperature, pressure, and chemical compatibility of the materials.

Non-metallic Gaskets

Non-metallic gaskets are mainly manufactured from rubber, graphite, PTFE, and compressed non-asbestos fiber. These materials are used mainly for low-to-medium pressure ranges, where an excellent tight seal needs to be offered in situations requiring flexibility and chemical resistance. A non-metal gasket would be selected when operating at moderate temperatures and pressures and when the process media require the gasket materials to be soft, i.e., non-reactive, to the process hardware materials and media. They would also come in handy for a system in which easy installation and cost of gasket play a key role.

Metallic Gaskets

Metallic gaskets are for applications of high pressure and temperature, providing extraordinary strength and durability. I would consider metallic gaskets in handling extreme operating conditions that require the highest resistance to compression stress and thermal stresses. They are made of materials such as stainless steel, copper, or other alloys compatible with harsh environments and aggressive media. Due to their excellent sealing capabilities, they are preferred in the petrochemical industry, oil, and gas industry, and power generation. They cost more than non-metallic gaskets and require precision in installation, but in demanding environments, there is no contest for their performance.

Composite Gaskets

Composite gaskets offer a very versatile sealing solution by combining the advantages of multiple materials to obtain the right balance on the scale of flexibility, durability, and chemical resistance. These gaskets are made of layers or laminates of materials such as graphite, PTFE, or rubber bonded with metal inserts and are ideally used in applications needing reliable performance with widely varying service conditions regarding temperatures and pressures. These composite gaskets do not offer the superior mechanical strength and sealing performance associated with fully metallic gaskets, but their adaptability and affordability have gained them wide acceptance in chemical processing, water treatment, and general manufacturing industries. By making a judicious choice of composite materials, these gaskets cover a wide range of specialized operational requirements while providing sure and durable sealing.

How Flange Gaskets Work

Flange gaskets create a compressible seal between two flanged surfaces to prevent fluid or gas leakage. When the flanges are bolted and tightened, an adequate amount of pressure is exerted onto the gasket to compensate for any irregularities present on the flanges’ surfaces, thus resulting in a fairly tight seal. Application temperature, pressure, gasket material, and correct bolt torque all have their role in this sealing action; thus, consideration of them will yield the most appropriate gasket type while ensuring its correct installation to retain system integrity in a reliable and durable manner.

Sealing Mechanism

The sealing method of flange gaskets prevents leakage between the two connected surfaces. I can do this by compressing the gasket material after the flanges are bolted together, thus allowing it to fill surface irregularities and present a secure seal. Successful sealing relies on choosing the gasket material carefully, properly applying the bolt torque, and analyzing factors such as the temperature and pressure under which it operates. By keeping these three items in check, I can maintain an efficient and reliable sealing mechanism to support system integrity.

Preventing Leaks with Gaskets

Many key points need to be addressed to prevent leaks with gaskets effectively. First of all, the gasket material should be carefully selected to withstand the temperature, pressure, and chemical environment of the particular application. I check that flanges are aligned properly since improper alignment causes uneven stress to be applied to the gasket, which may lead to leaks. During installation, correct bolt torque is applied in a cross pattern to ensure even compression without over-tightening, thus avoiding damage to the gasket. Regular maintenance also goes hand-in-hand with prevention; inspection of the gaskets for any signs of degradation and wear should be carried out occasionally so that any problems can be sorted out long before actual leakage occurs. Following these criteria should assist me in maintaining a good seal and in ensuring peak system performance.

Importance of Proper Gasket Selection

Proper gasket selection is paramount to securing dependable and timely sealing. I consider such parameters as the system’s operational temperature; pressure; and the type of fluid or gas for which it is designed. For graphite, for instance, in high-temperature applications, I go with materials capable of withstanding extremes of heat, or metal, which shall not break down. Another consideration must be compatibility with the fluid using an unsuitable material that comes down to chemical degradation and early routing. In addition, I consider the flange surface, selecting a gasket of appropriate thickness and compressibility to enable sealing and thereby eliminate leaks. Having assessed all these aspects, I can choose for performance and longevity sources that are sure to meet the demands placed upon them.

Common Types of Flange Gaskets

Gaskets for flanges are basically divided into three types, depending on the design of the gasket and the materials used: non-metallic, semi-metallic, and metallic gaskets. Non-metallic gaskets, such as rubber, PTFE, or graphite, are flexible and have excellent sealing properties, hence it is best to use them in low to medium pressure and temperature applications. For semi-metallic gaskets, spiral wound and corrugated metal gaskets possess the advantage of metallic strength combined with non-metallic sealing elements, thus they can be used in environments with higher pressures and temperatures. Metallic gaskets are best for extreme working conditions and uphold the highest pressure and temperature with durability: ring joint and lens gaskets. Therefore, the types of gaskets used in the application depend on the factors like operating conditions, fluid compatibility, and surface finish of the flange.

Spiral Wound Gaskets

The spiral wound gasket imparts a versatile and impregnable sealing solution to extreme pressure and temperature conditions. It is made up of metallic winding and soft filler e.g. graphite or PTFE that are arranged in alternate layers. This arrangement provides a fantastic combination of metallic strength and filler elasticity; thus, it is fit for very demanding applications in the petrochemical, power generation and oil and gas industries.

To answer the questions, spiral wound gaskets are suitable where a dependable seal is required under changing pressures and temperatures. They are suitable for a very large number of fluids due to the vast array of filler materials available from which to choose. When choosing a spiral wound gasket, make sure to pick the material best fitting your operating conditions, and ensure that the gasket is perfectly mated with the flange surface for an optimal seal.

PTFE Gaskets

PTFE gaskets are used to provide maximum chemical resistance and produce dependable sealing under extreme temperature conditions. I recommend the use of PTFE gaskets when dealing with systems handling aggressive chemicals or needing non-contaminating seals, due to their non-reactive nature and ability not to degrade even in harsh environments. When selecting a PTFE gasket, one should always consider pressure, temperature, and chemical compatibility of the application alongside with fitment procedures, which are paramount for a flawless seal. This includes correct compression of the gasket and ensuring proper alignment with the flange.

Corrugated Flange Gaskets

Corrugated flange gaskets make an apt choice if resilience and adaptability are required. They consist, however, of a grooved metal core with concentric anodised grooves, usually coupled with a soft sealant made of graphite or PTFE. This combination provides a dependable seal even during fluctuating pressures and temperatures, favoring challenging environments, such as in steam, gas, and chemical processing systems. Factors like operating pressure, temperature range, and compatibility with the medium should be taken into consideration whenever corrugated flange gaskets are considered. Their grooved shape allows for increased sealing performance and minimizes the chances of blowouts. And, proper installation shall be considered equally critical: being sure that the gasket is centered on the flange and evenly compressed will allow for an optimum seal. Lastly, periodic inspections and maintenance extend the gasket’s working life and further enhance the reliability of the system.

Factors Influencing Gasket Performance

Material Selection

The gasket’s material is one of the most important factors that influence its performance under pressure. Different materials offer varying resistances to temperature, pressure, and chemical exposure. Elastomers, for instance, are suitable for low-pressure systems, while metal gaskets do better in extreme heat and pressure. It is thus prudent to select a material that is somewhat compatible with the medium within the system; otherwise, it may degrade or fail during operation.

Surface Finish

The flange surface finish has great bearing on the gasket’s sealing ability. A rough or irregular surface will never guarantee a proper seal since it will promote gaps, though an extremely smooth surface may prove counterproductive by reducing friction needed to prohibit slippage. Make sure that your surface finish matches that of the gasket for optimal seal.

Installation Practices

Installation has a significant effect on the gasket’s integrity, especially if a gasket gets installed improperly. Too much tightening can cause crushing and premature failure of the gasket, while too little tightening can cause it to leak. Ensuring equal compression during installation and following the manufacturer’s torque specifications will render the gasket reliable.

Operating Conditions

Knowing the conditions under which the gasket will be operating, covering temperature ranges, pressure levels, and chemical exposure, is a determining factor for the longevity of gaskets. Once a certain set of parameters goes beyond their limits, wear will be accelerated, leading to leaks or catastrophic failure. It is imperative to choose components that are initialized for given applications.

Materials Used in Gasket Manufacturing

Materials for gaskets tend to vary insofar as application specifics are concerned. In general: rubber gaskets made of Nitrile and EPDM are flexible and resist oils and chemical effects. Metal gaskets, commonly made of stainless steel or copper, are for environments where high temperatures and pressures prevail, owing to the need for durability. Composite gasket materials such as graphite or PTFE merge strength with adaptability to seal under varying operational situations. Each material is consciously selected depending on the scenario so as to offer maximum performance, guarantees, longevity, and compatibility with the demands of the system.

Environmental Considerations

The environmental implications of gaskets should be given due consideration alongside their intended functions. Whenever possible, I always choose materials that can be recycled or that have a low footprint, such as PTFE or any other biodegradable alternatives. Secondly, I consider the manufacturers’ environmental impacts in observing the suppliers’ practices in taking the greener path. Resistance to defects is another important factor, since defects mean leaks, wasted material, and spilled chemicals-downright negative on the environment. Products bearing ISO 14001 certification are sought to ensure that environmental considerations are taken into account while maintaining the practical requirements.

Pressure and Temperature Ratings

While considering pressure and temperature ratings, I verify the ability of the materials of construction to withstand the actual operating conditions required of the application. I do this by checking the limits of maximum pressure and temperature that are stated by the manufacturer and whether they fit into the demands of the system. In this way, I’ll avoid any failure in time and so maintain safety and efficiency. Then I will also always cross-check these ratings against the related industry standards so that reliability and actual field consistency are ensured.

References

-

OneMonroe – What Is a Flange Gasket?

This article explains the purpose of flange gaskets in sealing the space between two pipe sections. -

Durlon – What is a Flange Gasket? Types, Uses, and Selection Guide

A comprehensive guide on flange gaskets, their mechanical role, and how they prevent fluid or gas leakage. -

DXT Seals – Flange Gaskets: Types, Benefits, and Applications Explained

This source highlights the benefits of flange gaskets in maintaining system efficiency and preventing leaks.

Frequently Asked Questions (FAQ)

What are different types of flange gaskets used in piping systems?

There are various types of flange gaskets used in piping systems, including metallic gaskets, non-metallic gaskets, and composite gaskets. Each type fulfills a different purpose in a particular application. For example, a spiral wound gasket is used quite often in high-pressure environments because it can withstand extreme conditions to provide a reliable seal. While rubber gaskets, on the other hand, are also more flexible and tend to provide a good seal in low-pressure situations. The material from which the gasket is made can substantially affect its ability to prevent leakage.

How do flange gaskets work to prevent leaks?

Flange gaskets form a seal between two flanges to keep fluids or gases from escaping. As the two flanges are brought together, the gasket is pressed to close the gaps on the flange surface and ensure a tight seal. Compression is a requirement for retention of pressure and to avert leakage. Different types of gaskets, including soft gaskets or semi-metallic gaskets, offer various sealing performances according to their applications. Understanding how these gaskets work could greatly improve the reliability of piping systems.

What is a raised face flange and its importance in gasket applications?

A raised face flange features a portion that is raised above the flange surface, an improved sealing surface for gasket applications. It basically focuses the sealing force on the gasket to help prevent leaks. Under high pressure and temperature, the raised face is best used with the right gasket type, such as spiral wound. Raised-face design assists in the proper alignment of the gasket material to be compressed evenly and reduces the chances of leakage.

Why are gaskets considered essential in the oil and gas industry?

The oil and gas industries view gaskets as indispensable in ensuring the safe and efficient operation of piping systems. They are more crucial in providing a reliable seal between flanges and preventing leaks of dangerous materials. Very high pressure and temperature conditions are common in such an environment; hence the need to choose the right type of gasket, such as a PTFE gasket or corrugated flange gasket. Therefore, the ability of gaskets to withstand extreme environments while remaining intact would contribute to enhancing the safety and reliability elements of operations within oil and gas.

What materials are commonly used for gasket manufacturing?

A few of the more common materials used for the manufacturing of gaskets are rubber, graphite, PTFE, and various metal combinations for semi-metallic gaskets. The selection of gasket material depends on several factors such as temperature, pressure, and the kind of fluid or gas to be sealed. For instance, PTFE gaskets are an excellent choice when chemical resistance is needed, while graphite gaskets are best suited for high-temperature applications. A knowledge of these materials can aid in making the correct choice in gasket type for a certain kind of flange design and legitimate sealing to prevent leaks.