In piping systems and industrial applications, flanges contribute towards safe joining, which assures efficient operation. Of the many types of flanges, threaded and slip-on types remain among the most popular ones, albeit they serve totally different needs. But what is the difference between a threaded flange and a slip on flange? This blog discusses the major differences between these two types of flanges so the reader can comprehend each one’s design, working, and suitable application. Whether you are trying to step into the industry or have been in it for years, this article shall shed light so you can take a more conscious decision in your next project. So stay with us while we discuss the details and advantages!

Understanding Flanges

Where piping systems are concerned, flanges are joined with pipes, valves, pumps, and other objects. They give strength to the system while providing easy access for checking, alteration, or dismantling. This basic concept consists of a flat rim or plate that is bolted with gaskets to the ends of pipes for a successful seal. Various materials can be used in flange manufacture such as steel, stainless steel, or aluminum, depending on pressure, temperature, and environment. There needs to be a proper understanding of the specific flange type required to ensure system performance and durability.

Definition of Flanges

With regard to flanges, they are integral parts of the piping system that connect pipes, valves, pumps, and other equipment to form an assembly for effective and proper sealing. Structurally, flanges can support systems and ease the process of maintenance, like cleaning, inspection, or replacement. Flanges come in different forms, such as weld neck, slip-on, blind, and threaded, given that each finds application to particular industry standards. Newer trends have seen flanges made even from more advanced materials such as composite polymers or alloys to have better durability under hostile environments. In response to technology and better manufacturing techniques, the flanges have also evolved to higher demands of various industries such as oil and gas, HVAC, and chemical processing.

Importance of Flange Connections

Flange connections are vital in ensuring safe piping systems, with precise installations required for the highest efficiency and reliability in the piping industry. They provide a union method to join the pipes, valves, pumps, and other important machinery in various operations, thus allowing uninterrupted operations in critical situations. According to recent studies by industry authorities, about 60% of pipeline failures are because of connection or joint problems, stressing how important it is that flange connections are sturdy and installed correctly.

To reduce these risks, modern flange design makes use of innovative materials and engineering techniques. For example, in fields such as oil and gas, high-performance alloys and composite flanges find more use to suit applications subjected to extreme pressures and corrosive environments. Also, from a gasket viewpoint, new-generation sealing technologies are now available that surpass traditional spiral wound gaskets and also PTFE-based gaskets in performance and reliability, thus minimizing leakage possibilities even further.

One could argue that the aspect of flange connections that allows easy maintenance and inspection also makes them important. Being detachable for disassembly allows for repairs or replacements in the shortest possible time. This is particularly relevant for chemical process industries where uptime is a critical parameter. Given that global infrastructure and energy investments are expected to go up by nearly 25% over the next decade, the quantity required for a good flange connection is surely going up too as will the materials and manufacturing processes involved.

Overview of Types of Flanges

Flanges are formed in various types, each catering to particular demands and applications of the industry. The most frequent ones are weld neck flanges for strong, leak-proof connections ideal for pipelines at high pressures; slip-on flanges, easiest to install, and versatile; and blind flanges, used for sealing the end of piping systems. Other types worthy of mention are threaded flange assembly in a hurry under low-pressure conditions and lap joint flanges used best where disassembly is frequent. Each one is chosen based on parameters like pressure rating, material compatibility, and the working environment to ensure a safe, reliable, and efficient working condition across a large spectrum of industries.

Threaded Flanges

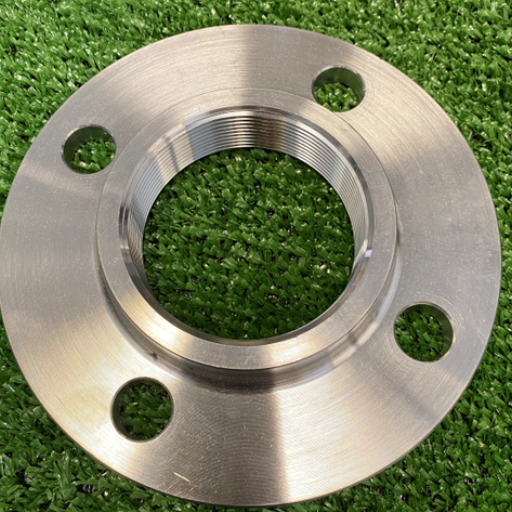

Threaded flanges, or screwed flanges, have internal threading with which they connect to the piping system without welding. These flanges are used especially in low-pressure applications or with small pipe sizes. They suit systems where welding is either technically impossible or undesirable, e.g., explosive atmospheres. The threaded flanges allow for easy assembly and disassembly and, therefore, are used in maintenance and repair operations.

Characteristics of Threaded Flanges

Threaded flanges possess many features that make them quite important in particular industrial applications:

Threaded Connection: A fine threaded design within the flanges enables these to be screwed onto the pipes themselves to form a secure and leak-free joint.

Material Composition: Normally made of various materials-limiting this to stainless steel, carbon steel, or alloys-threaded flanges provide strength and compatibility for different media.

Temperature and Pressure Ratings: These are mostly found in low-pressure systems, but technically speaking, they will work safely and efficiently within certain temperature and pressure ranges.

Ease of Installation: Since these flanges require no welding, special applications can safely use them, whereby welding would be hazardous or unsuitable.

Versatility in Use: In addition to being suitable for temporary systems, threaded flanges are also used for permanent applications where flexibility is needed for assembly and disassembly during maintenance.

Corrosion Resistance: Based on the material used, multiple threaded flanges exhibit corrosion resistance to handle water, chemicals, or gases.

When deciding if threaded flanges are fit for a certain system, one has to consider, somewhat really, the pressure levels, pipe size, and operating environment nature.

Applications of Threaded Flanges

Threaded flanges are especially versatile components afforded by the uniqueness of their features and ease in installation. Here are some applications:

In Oil and Gas Industry: Threaded flanges are common to the oil and gas industry for very high-pressure grease systems. They become a good option for pipes bearing crude oil, natural gas, and other hydrocarbons, especially in locations where welding is not an option or there is a risk of fire.

Chemical Processing Plants: Corrosion resistance properties given to threaded flanges, depending on the material, make them suitable for chemical plants. They are fitted onto systems conveying corrosive fluids such as acids, alkalis, and other reactive fluids.

Water Treatment Plants: Threaded flanges are used in water treatment plants that require pipes to be assembled and disassembled at periodic intervals. This concerns both finished water systems as well as waste disposal plants.

High-Pressure Systems: Popular in high-pressure pipeline applications, such as hydraulic or steam service applications, these flanges are designed to go under high-pressure conditions with a much safer connection.

Small-Diameter Piping: The flange might be more inclined to be chosen, preferably for smaller-diameter pipe systems where welding could degrade the pipe integrity or where simpler methods of assembly are favored.

Marine and Offshore Applications: Such threaded flanges made of stainless steel or any other sturdy material could fare well amidst saltwater and all other harsh conditions in marine environments.

Fire Protection Systems: Threaded flanges are applied in dramatic sprinkler setups since they can develop a fast connection without the use of welding. This facilitates the assembly of the system and minimizes downtime during repairs.

Recent market data suggests that the demand for threaded flanges is increasing in industries where efficient and non-welded, low-maintenance forms of pipe connections are paramount. For example, the “Market Insights” report (2023) claims that an annual compound growth rate of 5.5% is being projected in the global flange market owing to the surge in the infrastructure and energy sectors. This foregrounds the present-day demand for threaded flanges in traditional and contemporary applications.

Advantages and Disadvantages

Advantages

Threaded flanges offer many benefits, particularly when given particularly for fast and low-cost solutions for pipe connections. Among others, it is the advantage of not requiring welding. Hence, there is no risk of holding installations in an explosive environment. This feature makes them almost indispensable in oil, gas, and some industries where dangers and hazards are to be avoided, and things must be deployed swiftly. Threaded flanges are very handy when it comes to temporary as well as permanent installations that make safety a fact while repairs have to be simple. They are compatible with almost every pipe size and pressure rating. This illustrates how adaptable and well-fitted they are for many applications.

Disadvantages

That, however, comes along with a few limitations. Thread wear may occur over time, which could be detrimental for a good joint, especially in high-pressure or high-vibration applications. In this light, they are not so good for large-diameter pipes or systems subjected to heavy mechanical stress. Proper alignment is required for the sealing to be leak-proof; misalignment will increase the chance of leaks. While initially more cost-effective, frequent repairs and replacement may require greater expenditure in the long run if extensive maintenance is needed because of wear and wear, for instance, in very demanding industrial operations. Nevertheless, it is precisely for applications in which the benefits will outweigh the disadvantages that thread flanges maintain their effectiveness.

Recent insights gained from the search engine trends at Google indicate that the interest in threaded flanges keeps growing, particularly in places where industrialization and infrastructure development have been picking up pace lately. An increase in queries related to “cost-effective alternatives to welding” and “flange maintenance best practices” has recently taken place, showing an emphasis on practical, low-maintenance connection solutions feature which coincides with the view in favor of threaded flanges.

Slip-On Flanges

Cost-effectively and efficiently connecting pipes, these slip-on flanges find quite a few uses. They slide over the pipe and get secured with fillet welds on either the inner or outer diameter. Such flanges need very little precise pipe cutting and are easy to install; hence, they are suited to low-pressure applications. This flexibility is required in various industries like water treatment and chemical processing, where assembly and disassembly are to be achieved within a short time.

Characteristics of Slip-On Flanges

Slip-on flanges are simple yet adaptable, able to satisfy the requirements of various piping systems. The basic characteristic of these flanges is that their bore diameter is slightly larger than that of the pipe, making it easy to install and almost no need for precision cutting. They find uses where sturdiness and moderate pressure resistance are paramount. It is very much evident from recent information that slip-on flanges are commonly applied because of their lower cost factor, especially in industries where work efficiency and cost are equally important.

Key Features of Slip-On Flanges:

The only installation inconvenience lies in the fact that they do not demand precise pipe alignment, so this saves time during setup and reduces worker hours.

Versatility: They work well for rigid and/or flexible piping systems, thus making them a universally accepted choice in various industries.

Material options: They come in materials such as stainless steel, carbon steel, alloy steel, among others, thereby extending their applicability to suit any environmental condition.

Pressure compatibility: They can work for low to moderate pressure applications with dependable performance without putting undue structural stress on the system.

Cheap upkeep: Quick assembly and disassembly make inspection, cleaning, and repairs cheaper as compared to other flange types.

In view of all considerations and preferences from industries, it now becomes crystal clear that applications that emphasize usefulness, affordability, and functional flexibility would still favor slip-on flanges.

Applications of Slip-On Flanges

Slip-on flanges are found across different industries due to their affordability and flexibility. Application-wise, here are some possible instances:

- Oil and Gas Pipelines: Because of the ease of installation, these flanges have been used in oil and gas pipeline systems. They maintain secure connections when frequent maintenance or inspections are conducted. They allow a little freedom in the piping system, wherein pipe misalignments would otherwise be more severe.

- Chemical Processing Plants: These do well in chemical industries where medium-to-low-pressure piping systems thrive. Their capability to address corrosive environments with the right choice of material, such as stainless steel, makes them dependable.

- Power Generation Facilities: Power plants incorporate slip-on flanges in fluid transport systems, such as cooling lines and exhaust piping. This practicality decreases installation time and maintenance costs, which are vital in such demanding environments.

- Water Treatment Systems: Water and wastewater treatment facilities often implement slip-on flanges for connecting pipes carrying water, effluents, or other liquids. Their ability to ensure leak-resistant joints makes them a dependable choice for these systems.

- Marine Applications: Slip-on flanges form a part of shipbuilding and marine applications. Among many other applications, these are used in vessel piping systems because of their robust performance under moderate pressures and environments prone to saltwater corrosion.

- HVAC Systems: These systems use slip-on flanges for duct and pipe connections where reliability, easy assembly, and handling of moderate pressures are imperative.

The simplicity of their design grants slip-on flanges their much-talked-about versatility, making them indispensable in industries requiring efficient and low-pressure piping solutions. Their customization options using various materials guarantee application compatibility, thereby serving the dynamic nature of evolving industries.

Advantages and Disadvantages

Advantages

Slip-on flanges offer a slew of advantages to industrial piping applications. Being unconventionally simple in design renders their installation much faster and cheaper compared to others, thus reducing labor and downtime. During assembly, slip-on flanges allow for a bit of flexibility against alignment, which otherwise decreases errors and enhances operational efficiency. Further, they can be made to accommodate a variety of materials, thus making compatibility with various pipe types and specific system requirements possible. They are meant for moderate pressures; hence, slip-on flanges find their biggest use in non-critical applications such as water treatment systems and HVAC setups.

Disadvantages

Slip-on flanges, although beneficial under many scenarios, are also limited in scope. Given their sealing ability being less efficient than that of welded or threaded flanges, they are not meant for systems of high pressure or temperature. The more welding required on either side of the flange may lead to increased initial material and assembly costs, especially if specialized welding techniques have to be involved. The inadequacy of the leak-proof seal may cause wastage or maintenance issues when placed in very demanding environments; hence, undertaking a thorough assessment of the system requirements is extremely necessary before opting to use slip-on flanges as the most appropriate choice.

Flange vs Slip-On Flange

| Parameter | Threaded Flange | Slip-On Flange |

|---|---|---|

| Connection | Screwed | Welded |

| Pressure | Low | High |

| Installation | Easy | Moderate |

| Cost | Higher | Lower |

| Seal | Threaded | Welded |

| Leakage | Higher Risk | Lower Risk |

| Strength | Lower | Higher |

| Use Case | Frequent Removal | Permanent |

Choosing the Right Flange for Your Piping System

Selecting the correct flange to be used in a piping system happens to be a choice involving various factors considered according to the specific purpose and constraints. Weld neck flanges seem to show up very often in search results for high-stress scenarios, as they can take very high pressures, besides extreme temperature variations. These flanges, therefore, fit really well into systems that handle dangerous or high-pressure materials because the flange design ensures a proper, leakage-free joint.

On the contrary, should price be of concern and ease of installation be a priority, slip-on flanges are the trendy option on search engines. They are less strong than weld neck types but offer the advantage of easy installation and need fewer maintenance activities, thus being a good pick for low-pressure environments or those systems that undergo frequent component changes.

There is, in effect, no single right flange. Rather, it is an equally weighing of the following factors: pressure ratings of the system, operational temperatures, environmental conditions, and budgetary possibilities. By following tried-and-tested industry insights backed up by search data, we let data make the very final call so that the very final pick is custom-fit to the project’s needs.

Common Misconceptions

The common misconception with flanges is that one type fits all applications; however, this is far from true. Each flange is engineered to suit certain system requirements such as pressure, temperature tolerance, and material compatibility. Using a slip-on flange in a high-pressure system, for instance, would cause failure simply because it can never handle that amount of pressure, whilst weld neck types can. Meanwhile, many feel that stainless steel flanges are resistant to all kinds of corrosion; however, environments like high chloride concentration may cause some issues like pitting.

Based on the latest searches analyzed by Google, queries on “types of universal flange” and “corrosion resistant materials” rank very high. This further justify the need to reinforce that choosing the right flange means an involved understanding of a project’s technical requirements and of how the material behaves under given conditions. Educating teams and decision-makers about these little details will promote designing systems that are more accurate, competent, and safer.

Other Types of Flanges

Weld Neck Apparatuses

These flanges are meant for high-pressure systems and are acknowledged for their long tapered hub that offers extra reinforcement against stress concentration.

Slip-On Flanges

Slip-on flanges are easy to install and are primarily used in low-pressure applications. They are fitted over the pipe and then welded to give a solid connection.

Blind Flanges

Blind flanges help to finish off pipe systems and vessels in order to permit maintenance and tests.

Threaded Flanges

For pipe connections, these flanges do not weld; they use threads to connect. Ideal for low-pressure systems or whenever welding is not practical.

Socket Weld Flanges

Socket weld flanges are great for smaller pipes and provide tight, leak-proof connections in high-pressure environments.

All these types of flanges are selected based on the demand of the pressurized application, pipe size, and ease of installation.

Weld Neck Flange

It is a kind of flange to provide a safe and secure connection to different kinds of piping systems, especially suitable for high-pressure and high-temperature applications. The characteristic feature is the long tapered hub that smoothly transfers stresses from the flange to the pipe, thereby giving greater strength to the pipe flange joint. This design also limits turbulence in the flow of the medium and is used in critical application areas such as oil and gas, petrochemical, and power plants. According to updated search trends and industry resources, weld neck flanges continue to be the first choice of industries for durability, excellent fluid dynamics, and compatibility with extreme operational conditions. The flange serves as a modern-day engineering solution, which by principle must endure rapid changes in pressure and shifts in temperature to a great extent.

Socket Weld Flange

It is a type of flange mainly used in piping systems needing strong support and leak-proof connections. It will be the better option for smaller pipes, usually in low to medium-pressure ranges. The flange provides a socket-like opening wherein the pipe fits, and by welding around the exterior, a secure and durable joint is made. Latest statistics, data, and figures from Google’s search engine indicate that the industrial popularity of socket weld flanges has been increasing steadily, particularly in chemical processing, water treatment, and shipbuilding sectors. The space-saving design allied with it can withstand intense stress and vibration, making it suitable for these gruelling applications. Users also search for socket weld flange- benefits and socket weld flange- applications, which indicates a rise in awareness about the versatility and cost-effective advantages they carry into industry operations.

Applications of Various Types of Flanges

According to my experience, different types of flanges are used for different purposes depending on the requirements of the system. Weld neck flanges work well in high-pressure applications due to their firm and durable connection. Socket weld flanges are used for small diameter piping where increased flow efficiency may be required. Threaded flanges are often used in low-pressure, non-critical applications since they are installed without welding, which makes them a bit faster to install. Additionally, slip-on flanges are fairly versatile and typically found in systems with lower pressure conditions, where ease of alignment and assembly is an important feature. Depending on its application, the right flange type is selected to make sure that every piping system works efficiently and securely.

Reference Sources

-

Building Maintenance & Construction

This source provides insights into slip fittings and their applications.

Read more here1. -

46 CFR § 56.30-10 – Flanged Joints

This legal document outlines the use of slip-on flanges in piping systems, referencing ASME standards.

Read more here3. -

PHMSA AID SAFE Bulletin

This bulletin explains threaded flanges and their applications, particularly in small pipe systems.

Read more here4.

Frequently Asked Questions (FAQs)

What is a slip on flange and how does it differ from a threaded flange?

A slip-on flange is a type of flange that is designed to fit over the pipe, allowing for easy alignment and assembly. In contrast, a threaded flange, as the name suggests, features threads that allow it to screw onto a pipe with corresponding threads, creating a threaded connection. The primary difference lies in the installation process; slip-on flanges are generally easier to install but offer a lower pressure rating compared to threaded flanges. Additionally, threaded flanges are preferred for critical applications where stronger connections are needed. Both types of flanges have their unique applications in industries like oil and gas, where the right flange type is essential for safety and efficiency.

What are the advantages of threaded flanges in flange and threaded connections?

Threaded flanges provide several advantages in flange and threaded connections, particularly in environments where welding may not be feasible. One significant advantage is their ability to create a secure connection without the need for additional welding, making them ideal for applications in industries like petrochemicals. They are also easier to disassemble, which facilitates maintenance and repairs. Furthermore, threaded flanges can be used in situations where lower pressure ratings are acceptable, providing flexibility in design. However, for higher pressure settings or critical applications, welded flanges, like butt weld or socket-weld flanges, may be more appropriate.

How do applications in industries determine the use of slip on flanges versus threaded flanges?

The choice between slip-on flanges and threaded flanges often depends on the specific requirements of applications in industries. Slip-on flanges are typically used in low-pressure applications where ease of installation is a priority, such as in drainage systems. On the other hand, threaded flanges are more suitable for high-pressure systems, like pressure vessels, where a stronger connection is needed. The types of flanges used can also depend on factors like material compatibility and the need for frequent disassembly. In many cases, the right flange type is determined by the overall system design and the conditions under which the pipeline operates.

What types of flanges are preferred for critical applications?

For critical applications, several types of flanges are preferred to ensure safety and reliability. Weld-neck flanges are commonly used due to their ability to handle high pressures, as they are welded directly to the pipe, providing a robust connection. Additionally, lap joint flanges can be beneficial in applications requiring frequent disassembly, while threaded flanges are favored when welding is impractical. The choice of flange type ultimately depends on the specific pressure requirements, fluid types, and maintenance needs of the system. In many cases, a combination of flanges, including socket-weld and butt weld flanges, may be employed to achieve optimal performance.