From large-scale construction projects to intricate machinery systems across every industry, flange bolts play a crucial role as heavy-duty fastening solutions. Unlike regular bolts, they feature an integrated washer-type flange that distributes loads more evenly and provides superior grip stability. This comprehensive guide explores the key applications, advantages, and specifications of flange bolts across machinery, automotive engines, construction sites, and beyond.

Introduction to Flange Bolts

Flange bolts are specialized fasteners designed with an integrated flange below the head that acts as a built-in washer. This unique design ensures:

- Even load distribution across connected surfaces

- Increased grip strength and stability

- Reduced loosening risk during operation

- Faster assembly process without separate washers

These fasteners are widely used in construction, automotive, and machinery industries where secure and dependable fastening solutions are essential.

Definition and Key Features

Flange bolts combine a bolt and washer in one piece, providing maximum efficiency by eliminating the separate washer installation step during assembly. Their integrated design makes them indispensable in engineering and industrial projects requiring:

- Sturdy and reliable connections

- High-strength stability

- Even load distribution

- Easy installation

Components: Flange Nut and Washer Integration

The flange nut features a hexagonal design with an integrated circular flange base that:

- Disperses pressure evenly from the nut

- Prevents material damage

- Provides secure grip without separate washers

- Simplifies installation process

- Reduces assembly time significantly

Common Applications Across Industries

Automotive Industry

- Exhaust systems – Secure mounting with even pressure distribution

- Suspension components – Reliable fastening under constant stress

- Engine assemblies – High-strength connections for critical components

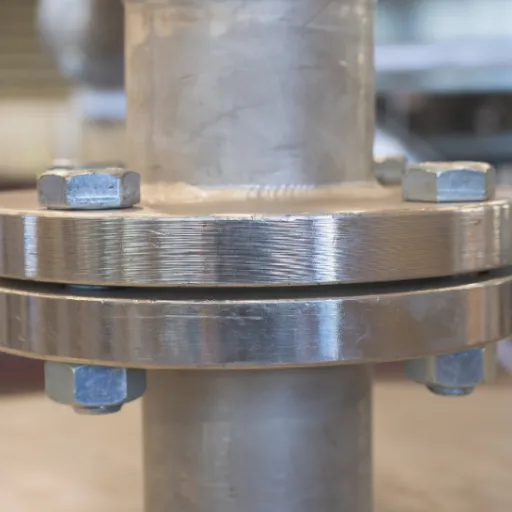

Construction and Manufacturing

- Heavy machinery fastening

- Structural assemblies requiring strength and stability

- Piping systems in industrial applications

- Equipment mounting in harsh environments

Types of Flange Bolts

Key Insight: Flange bolts vary by design, materials, and applications, with each type engineered for specific requirements and environmental conditions.

Standard Flange Bolt Types

| Type | Key Features | Primary Applications |

|---|---|---|

| Standard Flange Bolts | Circular flange under bolt head for force distribution | General construction, automotive applications |

| Metric Flange Bolts | Metric thread pattern for precision fitting | Manufacturing, engineering, international standards |

| Stainless Steel Flange Bolts | High corrosion resistance and durability | Marine, chemical, outdoor environments |

| High-Strength Alloy Flange Bolts | Enhanced strength and toughness materials | Heavy-duty construction equipment, machinery |

| Serrated Flange Bolts | Serrations on flange surface for increased grip | Automotive, mechanical assembly, vibration resistance |

Specialized Bolt Head Designs

12-Point Bolts vs. Hex Head Bolts

| Feature | 12-Point Bolts | Hex Head Bolts |

|---|---|---|

| Design | Twelve-point head design | Six-sided hexagonal head |

| Torque Application | Higher torque without stripping | Standard torque with basic tools |

| Space Requirements | Smaller engagement angles in tight spaces | Requires more clearance for wrench access |

| Best Applications | Aerospace, automotive, heavy industrial machinery | General construction, mechanical applications |

| Advantages | Equal pressure distribution, precision | Simplicity, wide availability, cost-effective |

Hex Bolt Variations

Standard hex bolts come in several variations tailored for different environmental conditions:

- Standard Hex Bolts – Most common type for general applications

- Galvanized/Zinc-Coated – Enhanced corrosion resistance for outdoor use

- High-Grade Bolts (Grade 8, A325) – Maximum tensile strength for structural connections

- Fully Threaded – Precision adjustment capabilities

- Partially Threaded – Better shear strength in load-bearing applications

Flange Bolt Specifications

Size Considerations

Proper sizing is critical for reliable performance. Key factors include:

- Diameter – Must match flange bore specifications

- Length – Adequate thread engagement without excess

- Thread pitch – Compatibility with mating components

Popular Standard Sizes: M10, M12, ½-inch are commonly used in pipelines, automotive assemblies, and industrial machinery applications.

Material Selection Guide

| Material | Advantages | Best Applications | Considerations |

|---|---|---|---|

| Carbon Steel | Cost-effective, adequate strength | Low to medium stress environments | Limited corrosion resistance |

| Stainless Steel | Excellent corrosion resistance | Marine, chemical, moist environments | Higher cost, moderate strength |

| Alloy Steel | Superior toughness and durability | High-stress industrial applications | Cost vs. performance balance needed |

Understanding Torque Requirements

Proper torque application is essential for optimal performance:

- Material considerations – Different materials require specific torque values

- Environmental factors – Temperature, vibration, corrosive conditions affect requirements

- Standards compliance – Follow ASTM or ISO guidelines

- Safety margins – Avoid over-tightening to prevent failure

Choosing the Right Fastener

Key Selection Factors

- Material Compatibility – Prevent galvanic corrosion between dissimilar metals

- Load Requirements – Consider static vs. dynamic loading conditions

- Environmental Conditions – Account for moisture, temperature extremes, chemicals

- Thread Requirements – Choose coarse or fine threads based on strength/precision needs

- Standards Compliance – Meet relevant industry codes and regulations

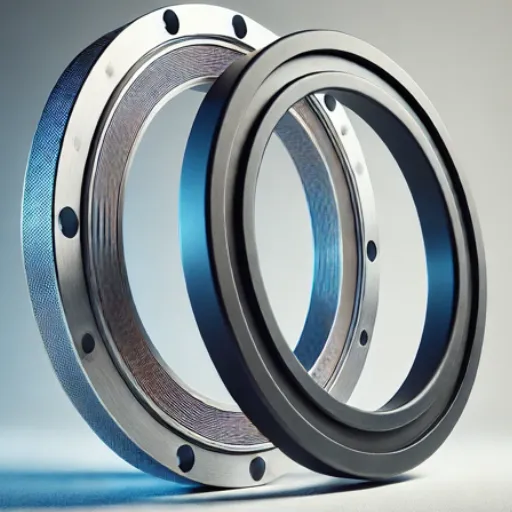

Flange Washers and Compatibility

Flange washers enhance joint performance through:

- Load distribution – Prevent stress concentrations

- Surface protection – Avoid damage under high torque

- Vibration resistance – Maintain joint integrity

- Universal compatibility – Work with various fastener types

Conclusion

Flange bolts represent a critical fastening solution across multiple industries, offering superior load distribution, enhanced grip, and simplified installation compared to traditional bolt-and-washer combinations. Understanding the various types, specifications, and applications helps ensure optimal selection for any project requiring reliable, heavy-duty connections.

Whether you’re working on automotive assemblies, construction projects, or industrial machinery, choosing the right flange bolt based on material compatibility, environmental conditions, and load requirements will ensure long-lasting, reliable performance in your applications.

References

- ISO Flanges – Technical Notes

This source from Cornell University provides technical notes on ISO flanges, including their alignment and pressure-related roles.

Read more here. - Fabrication Articles – Off-The-Shelf Parts You Should Know

This article from the University of Rochester explains the function of flange bolts, highlighting their washer-like plate under the head for pressure distribution.

Read more here. - Flange Bolt Failure Analysis – CORE Scholar

A scholarly article from Wright State University discussing flange bolts in gas turbine engines, focusing on their performance under high stresses.

Read more here - Top Flange Bolt Suppliers in China

Frequently Asked Questions (FAQ)

What are flange bolts used to connect?

Flange bolts are used to connect two components, typically in a flange connection. These fasteners feature a flange at one end, which helps distribute the load more evenly across the surface of the materials being joined. This design is particularly beneficial in applications where strength and durability are paramount, such as in mechanical assemblies and piping systems. Flange bolts are commonly used in various industries, including construction and manufacturing, to ensure a secure and stable connection. Properly using flange bolts in combination with flange nuts and washers can enhance the reliability of the assembly.

What are the common types of flange bolts?

There are several types of flange bolts, including hex head bolts and 12-point bolts. Each type serves specific purposes based on the application requirements. Hex bolts are referred to as such due to their hexagonal head design, allowing for easy tightening with standard tools. 12-point bolts provide an alternative head design that can be advantageous in tight spaces. Depending on the project’s needs, selecting the appropriate type of bolt and ensuring compatibility with flange washers and nuts is crucial for optimal performance and safety.

What is the proper torque for flange bolts?

The proper torque for flange bolts is essential to achieve a secure connection without over-tightening, which can lead to material failure or deformation. Torque specifications can vary based on the bolt material, size, and application, so it’s important to consult manufacturer guidelines or a torque chart. Using a torque wrench can help ensure that the bolts are tightened to the correct specification, maintaining the integrity of the flange assembly. Additionally, factors such as lubrication and the presence of lock washers can affect the required torque values.

What types of flange nuts are commonly used?

Common types of flange nuts include serrated and non-serrated flange nuts. Serrated flange nuts, with their built-in serrations on the flange, provide enhanced locking capabilities, reducing the risk of loosening due to vibrations. Non-serrated flange nuts offer a smooth surface and are suitable for applications where a more aesthetic finish is desired. Both types are designed to work effectively with flange bolts, ensuring a secure connection across the flange. When selecting flange nuts, it’s crucial to consider the compatibility with the specific type of bolt being used to ensure optimal performance.

What materials are flange bolts typically made from?

Flange bolts are typically made from steel, which is the most common bolt material due to its strength and durability. However, they can also be made from stainless steel, aluminum, and other alloys depending on the environmental conditions and specific application requirements. Choosing the right bolt material is essential, as it impacts the fastener’s resistance to corrosion, temperature, and mechanical stress. For example, stainless steel flange bolts are often used in marine applications due to their corrosion-resistant properties. Always consider the operating conditions when selecting the material for flange bolts to ensure longevity and reliability.