The matter of choosing between thinner and thicker gaskets in relation to sealing mechanical systems and performing at maximum efficiency can hardly be called trivial: the thinner and thicker gaskets are made for distinct applications, and selecting the right one could very well be a matter of efficiency versus an expensive hiccup! The article delves into the factors affecting gasket thickness, namely pressure, temperature, material compatibility, and use. By the end of this article, you will be equipped with the knowledge that will make your decision be the best it can be according to your specific requirements. Whether an old hand at engineering or looking to increase your technical know-how, this article is sure to give you the insights you need to optimize gasket performance.

Understanding Gasket Thickness

Depending on the thickness selection for gaskets, a good balance should be maintained between performance and life. The correct thickness depends on:

- Pressure: Higher pressure would often require a thinner gasket so that it can compress without excessive deformation, achieving a proper seal.

- Temperature: In the case of very high or very fluctuating temperatures, appropriate choice of thickness will not allow the gasket to fail.

- Material Properties: Out of all materials, they have different degrees of compressibility, where soft materials may require a thicker gasket for a better seal.

- Flange Surface Conditions: Have an irregular or rough surface that demands a thicker gasket to fill those gaps and achieve a good seal.

- Consider Application Issues: Consider aspects of the working environment such as exposure to chemicals and vibration, which may affect the thickness selection.

A thorough evaluation of the above factors would assist in choosing the ideal gasket thickness for enhanced performance and reliability in your particular application.

What is Gasket Thickness?

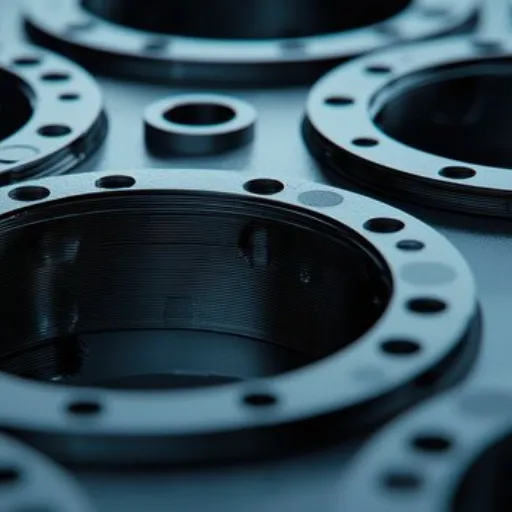

Gasket thickness is the measurement of the depth of a gasket, commonly expressed in millimeters or inches, whereas its indication is one element relating to performance and usefulness. It governs the capability of the gasket to seal joints between two surfaces and account for irregularities, surface imperfections, or gaps in between.There seems to be an increasing interest in defining gasket thickness for given areas of applications, like sealing in high-pressure, in aggressive chemical environments, etc. The choice of thickness is essentially a compromise, where flexibility is opposed by compression strength to ensure the strength of the gasket under operational stresses. With various recent developments in materials science, gaskets are being made with ever-higher precision and adaptability to allow the best selection of thickness for applications in the automotive, aerospace, and chemical processing industries, among others.

Importance of Gasket Thickness

The proper gasket thickness is crucial for an effective and efficient seal in any application. Being of the right thickness means it gets compressed enough to stop leaking and not so much as to deform the joint or even cause failure. It allows the gasket to fill surface irregularities, sealing in difficult conditions such as very high pressure, temperature fluctuations, or even aggressive chemicals. An incorrect choice for the thickness would cause inefficiency during operation or could cause wear or halt operations costing money. Hence, one has to do a complete analysis of the operational requirements in addition to the material properties that fit better in order to assess and decide the optimal thickness of a gasket to last over time.

How Thickness Affects Sealing Performance

The thickness of the gasket plays an important role in its sealing performance in terms of adaptability to irregularities and maintaining a reliable seal under adverse conditions. Thicker gaskets generally compensate for the surface imperfections better, resulting in better sealing on uneven or damaged mating surfaces; the downside is that they may relax or compress with the passage of time, especially when under a very high load. On the other hand, thinner gaskets resist creep better and retain their dimension, from which they benefit when used on applications with smooth, flat surfaces and stable sealing conditions. Ultimately, the choice of thickness is a compromise between adaptability and endurance toward actual pressures, temperature, and environmental conditions imposed by the application at hand.

Thinner Gaskets: Pros and Cons

Advantages of a Thinner Gasket

- Dimensional Stability Improvement: Thinner gaskets will not distort throughout time; instead, they keep the sealing constant.

- Thermal Creep Resistance: They resist steady mechanical pressure and temperature conditions.

- Typically for Smooth: In cases where sealing surfaces lay even and well-prepared, this is mostly attained.

There are considerations that favor choosing thinner gaskets in certain applications. Tighter seals can be achieved with lesser compression of material, which means that such gaskets would be more effective in sealing in low- and some medium-pressure environments. Thinner gaskets will make a good choice in resistance to extrusion and maintenance of their integrity under stable working conditions. They occupy less space due to their very compact design and minimize material use, thus offering a further avenue toward cost saving in application that requires a thin gasket. In short, if thinner gaskets are installed correctly under adequate surface conditions, they will perform satisfactorily while contributing toward slimmed-down and lightweight assembly designs.

Disadvantages of a Thinner Gasket

- Less Flexibility: They cannot accommodate irregularities and roughness on the surface.

- Reduced Load Tolerance: In conditions of oscillating pressure or heavy loads, it may be insufficient for sealing.

Limited Durability: In my judgment, thinner gaskets are less durable, especially in applications involving high pressure and/or high temperature, as by then they will be prone to wear much faster.

Reduced Seal Performance: I tried them and felt they would sometimes fail at keeping a secure seal on surfaces that are somehow uneven or strongly twisted.

Greater Sensitivity to Installation Errors: One problem I found is that those thinner gaskets have to be handled with care during installation because the momentum of the hole might damage them if not precisely positioned.

The decision for thinner gaskets needs a close look into the operational setting, so performance is guaranteed.

When to Use a Thinner Gasket

A thin gasket is used best when there is no clearance, and the application requires accuracy. They perform well with smooth flat surface systems that need a tight seal with no stress or pressure variations applied. They are further applied in low-pressure environments or where a compact sealing solution is needed due to tight space. Proper installation procedures must be ensured to aid the gasket in maximizing its sealing utility and duration.

Thicker Gaskets: Pros and Cons

Thick gaskets are considered better for uses where higher pressure or uneven sealing surfaces exist. They provide durability to endure and resist imperfections to maintain sealing under harsh conditions. Because of very high pressure, thick gaskets may be compressed unevenly and in that case, could lead to seal failure if not assembled properly. They occupy more space too, which can become another limitation in compact-sized systems. The selection of a thicker gasket depends on or is directly related to the application’s exact needs, involving pressure, temperature, and surface conditions.

Advantages of a Thicker Gasket

Thicker gaskets have several advantages, especially in places where durability and sealing are crucial. Due to their thickness, they can compensate better for surface irregularities to ensure a consistent seal even in cases where flange surfaces may be uneven or damaged. They are capable of absorbing more pressure levels and vibrations, which, in turn, makes them very much suitable in working environments where there exist some undesirable effects such as industrial machinery or high-pressure piping. Thicker gaskets have their own resistance to thermal expansion and contraction, an advantage required in situations where temperature fluctuates; nonetheless, an installation geared to thicker gaskets and the right choice of materials will be required for the best result.

Disadvantages of a Thicker Gasket

Thicker gaskets offer various benefits but still come with their challenges. One of the major drawbacks is their tendency to over-compress, potentially leading to deformation or outright failure under high pressure. Such thick gaskets might cause problems during installation since exact alignment and application of torque become even more critical for a proper seal. ActionAgainstTheThicknessness: Besides, the thicker gasket’s voluminous profile makes it less cost-effective when compared to his thinner childhood friend, considering applications where precision and material efficiency come to the fore. Finally, in the case where the working environment is spatially limited and demands a compact design, thick gaskets would never be an option, for they might stand in the way of how the system is configured.

When to Use a Thicker Gasket

When sealing against surface irregularities or considerable gaps between mating components, thicker gaskets should be considered. They work best under low pressure, as they compress and conform to the irregularities better. Also, they offer more room to bear movements and changes forced on them by thermal or mechanical stresses. Other times, they may actually benefit in sealing slight variations in the surface, such as preventing leakage since they conform to their irregularities. Also, one needs to consider particular engineering specifications of the system to weigh the practicality and efficiency of choosing a thicker gasket.

Choosing the Best Gasket Material

- Operating Temperature and Pressure: Select a material capable of resisting the temperature and pressure ranges of the system without degradation. Otherwise, an effective seal may not be maintained throughout time.

- Chemical Compatibility: Select materials that do not react with or degrade due to the chemicals encountered during use, for the sake of material degradation and potential leaks.

- Environmental Conditions: Consider outside environmental factors such as UV rays, moisture, or ozone, as these may have consequences on the durability and effectiveness of the gasket.

- Application-Specific Requirements: Assess the mechanical stresses, movements, and surface conditions the gasket should be subjected to. The material should be sufficiently flexible and conformable to ensure a solid seal.

- Compliance Standards: Verify if the material is approved per the standard requirements of the industry or regulation governing its application to assure safety and reliability.

By fully balancing these factors, you should be able to choose a gasket that offers optimal performance and longevity for your particular needs.

Popular Gasket Materials

Selecting gasket material depends on the requirements of your applicable project. Materials such as rubber and silicone are highly flexible and resistant to a wide array of chemicals, making them useful for dynamic sealing environments. Graphite and PTFE rank high in heat resistance and durability and are ideal for high-temperature applications. Metal gaskets preferred under extreme pressure conditions provide a solid seal. Composite materials from other types offer a possibility to stand under an extremely diverse environment. When you see such factors as chemical compatibility, temp resistance, compliance standards, and so forth, you bet the chosen material does satisfy the requirements of that application.

How Material Affects Thickness

The type of gasket required greatly affects the thickness of the gasket because of the inherent material properties of compressibility, elasticity, and strength. Soft materials such as rubber have thicker gaskets since they have been compressed to a greater extent to maintain the seal of varying conditions acceptable seal in the shallower depth. Harder materials such as metals are generally made thinner, as they have less ability to deform but more ability to sustain pressure when given very high-pressure conditions. Composite materials, which combine various properties of different materials, allow for a compromise in thickness depending on the application’s requirements, i.e., tolerance to temperature, exposure to chemicals, etc. When considering gasket thickness, it is important to look at how far the gasket deforms and conforms under load to achieve performance and sealing.

Durlon and Its Applications

With great sealing properties and the ability to adapt itself to various working conditions, Durlon materials find great versatility and use in industries such as chemical processing, oil and gas, and power generation. It sees applications in sealing gaskets and materials that need to withstand high pressure, incredibly high temperatures, and aggressive chemicals. The unique composition of Durlon offers superior durability and conformity, thereby guaranteeing to its performance in harsh conditions. Durlon can be a wise choice for ensuring the safety and efficiency of essential systems since it is available in various grades and thicknesses to suit different industry requirements.

Conclusion: Finding the Right Gasket Thickness

An adequate selection of gasket thickness is key to optimal sealing and system working conditions. The right thickness makes for a good sealing application during the working conditions, covering any imperfections on the face of the flange and preventing any blowouts or leakage. Working pressures, temperatures, face conditions of the flanges, and bolt loads experimentally determine the appropriate thicknesses. A special attention would need to be paid to ensure that the material and thickness comply with the particular requirements of your system with the help of a gasket manufacturer or by following industry recommendations to help preserve safety and increase efficiency.

Evaluating Your Sealing Solutions

During the sealing solutions process, the application of several considerations that influence their operational capacity and dependability should be considered. Begin with the operating conditions-pressure and temperature and media being sealed-which have a direct effect on selecting a gasket. Evaluate the flange surface for any kind of imperfection that would compromise the sealing operation; consider also the compatibilities of the gasket material with the media. Examine the bolt load requirements to ensure adequate compression of the gasket and to avoid leaks, or even blowouts. A systematic analysis of these parameters, with possible support from manufacturers or industry materials, will permit the selection of a sealing solution tailored to the system requirements, providing maximum safety and efficiency.

Final Thoughts on Gasket Thickness

The selection of gasket thickness is paramount in any industrial environment for ensuring a tight and properly functioning seal. The thickness depends upon the condition of the flange surface, type of temperature, and pressure being operated upon, as well as the mechanical strength properties of the gasket material. Thinner gaskets are said to seal better when flange faces are smooth and parallel because they can lessen the chance of creep, or relaxation, occurring in the gasket. If the flanges are uneven or damaged, then thicker gaskets will have to be used to compensate for surface irregularities and to ensure sealing. It would be highly advisable to check the manufacturer’s recommendations and industry standards to determine gasket thickness, balancing the requirements for durability, safety, and operational ease.

References

-

Hennig Gasket & Seals: This article explains why thinner gaskets often perform better, highlighting their greater blow-out resistance and reduced deformation under pressure. Read more here.

-

RAM Gaskets: This source emphasizes the benefits of using the thinnest possible gasket, particularly for sheet gasket materials, to enhance performance. Read more here.

-

Phelps Gaskets: This FAQ section discusses the advantages of thinner gaskets, including improved joint performance and reduced emissions. Read more here.

Frequently Asked Questions (FAQs)

Is a Thinner Gasket Better for Fluid Sealing?

Considering the thickness of the gasket and its appropriateness for fluid sealing, the nature of the application must be examined as well as certain features of the gasket material. Thin gaskets are often recommended because they can easily adapt to the irregularities in the flange surface, thereby improving the joint by way of reduced emission to leakage rates. A thin gasket will compress better torque-torque retention, hence maintaining satisfactory fastener torque. But thicker ones usually provide better resistance to blow-out forces and service durability in a higher-pressure and temperature environment. Ultimately, it ought to be suitable for the flange system and the materials involved to ensure efficient sealing.

What Are the Unique Properties of Thinner Gaskets?

Thinner gaskets go through certain distinguishing features, which are used for their advantage in the field of application. The less thickness in them makes them good for accommodating flange irregularities, which would then impede proper sealing. Thinner gaskets, however, can enhance the torquing ability and increase blowout resistance, especially in dynamic applications. Consideration of the thickness of the material and its creep relaxation property needs to be given special attention in as their performance affects that of the gasket. Usually, gasket material suppliers generally recommend thin gaskets wherever possible for a fluid sealing interface.

How Does Gasket Material Affect Thickness Selection?

The applicability of a gasket thickness largely depends on the choice of the gasket material. Different materials, such as semi-metallic gaskets or soft gaskets, have different levels of stiffness and compressibility, which means they respond differently in conforming to flange irregularities. Like, a soft gasket may work better at a thinner thickness since it can deform and fill gaps, whereas semi-metallic gasket-type gaskets must be thicker to perform well. It is always advised to consult with a gasket material supplier to select the appropriate one for a gasket given your specific application, such as torque retention or blowout strength.

What Are the Benefits of Using a Sheet Gasket?

The advantages of sheet gaskets make it popular in many industrial applications. They are custom-made for various flange sizes and shapes, giving a dependable sealing option. Thinner sheet gaskets should be used wherever possible to improve joint performance by limiting leakage while enhancing torque retention. Besides that, selection is made from many materials based on the needs of resistance to corrosion or to temperature change. So, the flexibility in design and material constitutes an excellent choice for sealing application needs.