As a premier manufacturer based in China, we specialize in engineering and producing high-performance flange nuts that exceed industry expectations. Our commitment to quality is unwavering, with every nut precisely crafted to meet stringent international standards like DIN 6923 and ISO 4161. Available with serrated or smooth flanges, our nuts provide exceptional clamping force and vibration resistance, guaranteeing unmatched reliability for your most critical assemblies. Partner with a dependable flange nut supplier and ensure your projects are built with superior strength and security.

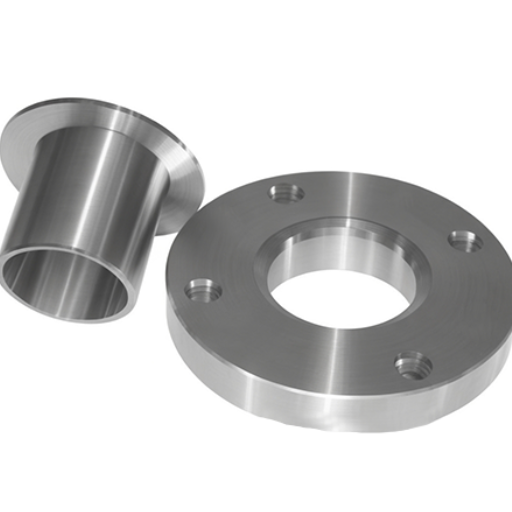

Understanding the differences between a blind flange and a backing flange becomes indispensable in piping systems, construction, or engineering works. While the joining and sealing operations of pipelines are...