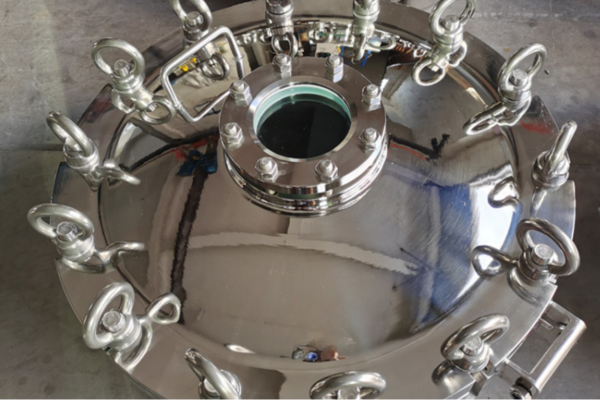

As a vital access solution for industrial systems, flange manholes provide a secure and repeatable entry point for inspection, cleaning, and maintenance. Primarily designed for pressure vessels, storage tanks, and large-diameter pipelines, these manholes utilize a robust, bolted blind flange cover. This assembly works in tandem with a high-performance gasket to create an impermeable seal, ensuring containment under both high pressure and vacuum conditions. Fabricated from superior-grade materials, including carbon steel, stainless steel, and specialized alloys, they deliver exceptional structural integrity and long-term resistance to corrosion, guaranteeing operational safety and reliability in critical process environments.

When it comes to industrial systems, a leaking flange gasket is a recurring and vexing problem that influences operational efficiency, safety, and maintenance costs. Understanding the reasons behind flange...