Every industry needs gaskets for sealing solutions reliability and durability across all possible applications. Can gaskets be plastic? Although the most traditional materials – rubber and metal – are used here, plastic gaskets are poised to carve out a whole new niche for themselves as the most modern and versatile alternative. Do plastic gaskets really exist? If so, what benefits do they have? This blog explores the plastic gasket world: their properties, applications, and why they’re becoming more popular somewhere along the line. Whether you are an engineer, a manufacturer, or just an enthusiast for new materials making modern engineering, this article will pave the way for you to comprehend the promise and applicability of plastic gaskets in today’s time.

Understanding Gaskets

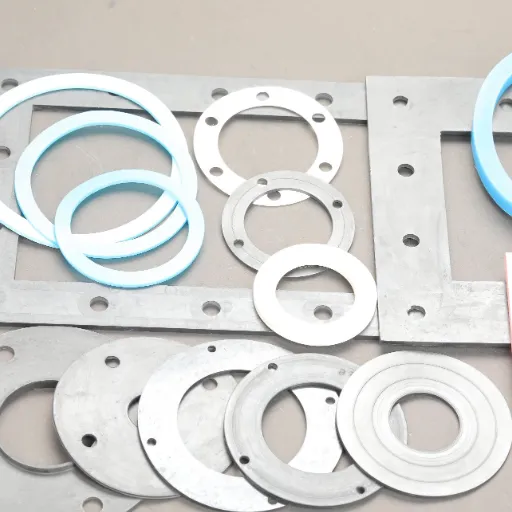

Gaskets are essentially mechanical seals used to prevent leakage from or into the joining surfaces while under compression. They serve as critical components within numerous industries and provide an effective seal for systems involving liquid, gaseous, and pressure etc. Generally, gaskets are made from rubber, silicone, metal, or even plastic, all materials with good deformability to adapt to irregularities on the mating face to secure a barrier. Leakage normally results from inappropriate application or wrong installation, making the right gasket job a matter of safety and efficiency in all instances, from automotive engines to industrial pipelines.

What is a Gasket?

A gasket is a mechanical sealing component that fills the space between two or more mating surfaces and prevents leakage of fluids or gases during compression. Gaskets are intended to endure diverse levels of pressure, temperature, and chemical exposure. In that regard, their adequate functioning is imperative to the proper operating and safety of equipment in a wide array of industries-almost as diverse as automotive, aerospace, manufacturing, and plumbing. By means of a sealing barrier between parts, the gasket accommodates surface irregularities, diminishes vibration in the system, thereby improving the work efficiency/performance of the system. Appropriate selection of the material and its installation greatly affect the service life and performance of the gaskets and, hence, their proper use in everyday applications as well as specialized ones.

Types of Gaskets and Their Uses

In my experience, there are several types of gaskets specific to particular applications. For example, metallic gaskets work well in high-pressure and high-temperature environments and are thus commonly employed in industries such as aerospace and automotive. Rubber gaskets provide the flexibility required for sealing applications needing some degree of movement and are also used extensively in odor blocking and waterproof applications, such as in plumbing. Spiral-wound gaskets combine metal and filler materials for extreme environment applications, commonly used for oil and gas pipelines. Non-metallic gaskets, such as those of cork or composite materials, are suitable for low-pressure applications because they deform better when facing irregular surfaces. Each of these gaskets exists to fulfill specific functions that ensure the safe and efficient working of various systems.

Can Gaskets be Plastic?

Can gaskets be plastic? Plastic gaskets constitute a more versatile and cost-effective option applied in many industries because of their durability and adaptability. Made of materials such as PTFE, PVC, or polyethylene, they respond well on exposure to chemicals and hence are suitable gaskets for acids, solvents, or other corrosive substances. Due to their light nature and ability to tolerate pressures and temperatures within moderate ranges, plastic gaskets find common application in water systems, food processing, and electrical insulation. Another advantage of these plastic gaskets is the ease of molding, which aids in customization to fit specific requirements.

What is a Plastic Gasket?

Plastic gaskets are sealing components made of various plastic materials to avoid leakage between two surfaces or joining parts. These gaskets are flexible and durable and offer great resistance against chemical agents, moisture, and environmental effects. Made from polymer varieties such as PTFE, PVC, or polyethylene, plastic gaskets are light in weight and economical while adapting well to an array of industrial applications. This quality makes them easy to customize for certain shapes and sizes that need a proper fit in systems such as pipelines, electrical enclosures, and machinery to ensure better performance and reliability.

Advantages of Using Plastic Gaskets

Plastic gaskets share some advantages that justify their widespread industrial use. They show high resistance to various chemicals and thus remain durable with little degradation when exposed to aggressive substances. Their low weight assures ease of installation, plus reduced strain on system components; plastic gaskets are also highly affordable, thus becoming an economical option during large-scale applications. Plastic gaskets have the ability to work well under variable temperature extremes while taking up high pressure, giving them reliability even when conditions become harsh. Due to their malleable character, plastic gaskets may be made to fit precisely into different systems, thereby leaving no spaces that can affect their usefulness.

Common Types of Plastic Used in Gaskets

The plastic gaskets are made of various materials, each selected depending on its properties and suitability for particular applications. Below are some of the most widely used plastics in gasket manufacturing:

| Material Type | Key Properties | Applications |

|---|---|---|

| PTFE (Polytetrafluoroethylene) | High chemical resistance, high temperature application, non-stick surface | Chemical processing, food industries |

| Nitrile Rubber (NBR) | Oil and fuel resistance | Automotive industry, industrial machinery |

| EPDM (Ethylene Propylene Diene Monomer) | UV-resistant, ozone and weather-resistant | Outdoor and weather-sealing applications |

| Polyurethane | Outstanding abrasion resistance and elasticity | Hydraulic and heavy-duty systems |

| Polycarbonate | Impact resistance and clarity | Electronic enclosures, specialized applications |

| PVC (Polyvinyl Chloride) | Cost-effective, water and chemical resistance | Plumbing, construction |

Important Note: Each application calls for a good knowledge of its specifications so that the correct choices of plastic might be made for the gaskets. Each plastic has a distinct advantage, guaranteeing both productive sealing and longevity under various conditions.

Material Selection for Gaskets

Selecting the right material for gaskets is dependent on crucial criteria, as the following:

- Operating Temperature: The material should have the ability to maintain strength and resist degradation at the specified working temperature, i.e., maximum and minimum temperature of application.

- Chemical Compatibility: Select the type that is compatible with chemicals or substances that it will come into contact with so as not to be prone to corrosion or degradation.

- Pressure Levels: The gasket material should be able to withstand the operating pressure so as to remain sealed and to stand without being crushed or deformed under the stress of its application.

- Application Environment: Whether the material will be exposed to UV, moisture, or other environmental factors should also be considered, as these may affect gasket life.

- Regulatory Standards: In some cases, products have to comply with specific industry or safety standards, such as FDA approval for food-grade gaskets.

One can identify a gasket material that will work most optimally and reliably for his or her special application by paying close attention to the above factors. Silicone, PVC, and rubber, for instance, are basic materials that provide an assortment in properties to adequately serve the needs.

Comparing Gasket Materials: Plastic vs Metal

When I am defining gasket materials and application suitability, I am thinking about their different characteristics. Plastic gaskets like PVC or silicone are generally more flexible, lightweight, and corrosion-resistant; thus, they are suited to cold-temperature applications and chemical-sensitive environments. Metal gaskets, though, i.e., stainless steel, are excellent in high pressures and high temperatures, for which endurance and strength are the requirements. In my opinion, plastic would be considered when chemical compatibility and cost come into play, whereas metal would be selected when utmost durability combined with resistance to extreme environments governs the choice. That being said, the final decision depends on the performance requirements of the particular application.

Custom Gasket Solutions with Plastic

Generally, plastics have been providing adaptable, cost-efficient solutions to the array of industries requiring custom gasket applications. This plastic material can be tailored to meet a wide range of needs, such as heat resistance, chemical compatibility, and durability, and therefore, be fit for hostile environments in industries such as aerospace and healthcare. Many plastics tend to be lightweight and, consequently, can be produced in an eco-friendly or recyclable version that works toward sustainability goals. Selection of the plastic type would therefore offer manufacturers an invisible way of selecting the best balance of performance, safety, and environmental concerns, with the regulations that these industries must adhere to.

Applications of Plastic Gaskets

Plastic gaskets are used in many different industries, thanks to their versatility and dependability. Applications in industries such as automotive are varied, involving processes of sealing and cushioning in engines, transmissions, and fuel systems. In the medical world, plastic gaskets assure airtight sealing in medical devices and various equipment. Aerospace applications are mostly about lightweight sealing solutions with great durability, whereas plumbing systems use them as gaskets to prevent leaks in pipes and joints. Their versatility allows these gaskets to work in several environments and hence become an essential component in both industrial and consumer applications.

Gasket Applications in Various Industries

Being flexible in application, gaskets are used in many industries. I have seen them applied in the automotive industry to create reliable seals for engines and transmissions, in the medical field to ensure precision and safety of devices, in aerospace applications where lightweight durability is crucial, and even in everyday applications where they prevent leaks in plumbing systems. Because gaskets are so adaptable to various environments, they become indispensable whenever a reliable seal is required.

Manufacturing Plastic Gaskets

Making plastic gaskets consists of a few integral steps which, if precisely followed, produce quality products: First, an appropriate plastic material suitable for the application method should be selected. It could be PVC, PTFE, or polyethylene. Depending upon the dimensions and design required, the material is molded or cut-by injection molding, die-cutting, or laser cutting. After formation, the gaskets are inspected for any defects and tested for durability and performance in accordance with standard industry performance. This assures of satisfactory and efficient gaskets serving almost any application.

Die-Cut Gasket Manufacturing Process

The production process for die-cut gaskets starts with the choice of the correct material for the particular application, whether it be rubber, foam, or plastic. Once the material is chosen, it is put on the die-cutting machine, wherein a sharp, pre-designed die cuts the material into the shapes and sizes required with extreme precision. The procedure allows for a high level of customization, which can meet very complex designs and tight tolerances. Upon the completion of the cutting process, the gaskets are furthermore inspected to ascertain that there are no defects and that they meet the standards for quality, performance and durability. This method is beneficial regards some very efficient and cost-effective processes, allowing versatility in the production of gaskets with a broad spectrum of applications in various industries such as automotive, medical, or electrical application fields.

Designing Custom Plastic Gaskets

Custom gasket design has to take into account factors that include application requirements, material characteristics, and environmental conditions. First, one must establish the element of the gasket under consideration: Is the gasket supposed to be sealing against pressure, or is it just for vibration dampening or insulating? The answer governs the selection of materials and design parameters. The plastic material must be suitable for operating conditions such as heat resistance, chemical resistance, or wetness resistance. One must calculate all critical dimensions, including thickness and shape, for complementary fit and sealing efficiency. Also, the design may have to consider regulatory standards and/or specific requirements for the particular industry to ensure full compliance and credible execution. Having considered these factors, an efficient, durable, and application-oriented custom plastic gasket can be produced by the manufacturer.

Quality Control in Gasket Production

Quality assurance in gasket making is a strict process that guarantees production to come up to a certain specification and performance level. It comprises stages of inspection into material selection, measurement and dimensional verification, and durability, whereby all are tested within the controlled working condition, such as pressure, temperature, or chemical exposure. Manufacturers use advanced techniques such as automated inspection to spot defects and inconsistencies in compression testing and tensile strength analysis. A guarantee for gasket reliability and safety is given by adherence to regulatory standards and certifications. Proper documentation and traceability in the entire production cycle are maintained to guarantee the transparency of airing about the continuous improvement.

Reference Sources

-

Best Materials to Use for Die-Cut Gaskets

This article discusses various materials used for gaskets, including plastic, and their applications. -

Plastic Gaskets from Nylon, LDPE/HDPE, Polycarbonates

A detailed overview of plastic gaskets made from materials like nylon, LDPE/HDPE, and polycarbonate. -

Why do we use rubber and plastic gaskets instead of metal

A discussion on the advantages of plastic and rubber gaskets over metal ones, including flexibility and cost-effectiveness.

Frequently Asked Questions (FAQs)

What types of gasket materials are available for plastic gaskets?

There are many materials for plastic gaskets, from nylon, neoprene, and other plastic compounds. These materials combine a broad spectrum of properties like chemical and heat resistance to suit applications. Nylon gaskets, for example, have low friction and superb wear resistance, which can be beneficial in mechanical systems. Apart from this, manufacturers also provide solutions where they can cut the gasket to the desired thickness and form it into any shape as required. Plastic materials, owing to their vast versatility, can be exploited to come up with an effective sealing solution in any given industry.

Are plastic gaskets and seals a good alternative to metal gaskets?

Yes, plastic gaskets and seals are employed as an alternative to metal gaskets. They have good durability and sealing properties, which suit most applications. Plastic gaskets also insulate against electrical properties, which may be crucial to certain electronic applications. They prevent the entry of contaminants into the system too, thereby ensuring their longevity and reliability. Plastic gaskets are available in a wide range of thicknesses and can be cut to any shape; thus, they remain inexpensive and can be customized to fit immediate needs.

Can plastic washers be used in conjunction with gaskets?

Plastic washers can indeed be used with gaskets to enhance the sealing as well as the insulation, preventing contaminants. Being made out of nylon, neoprene, etc., these washers complement the capabilities of gaskets in preventing the ingress of contaminants while allowing mechanical stability. Plastic washers are commercially beneficial in applications needs require seal plus some mechanical stability. This combination of plastic washers with gaskets will enhance the performance and life of the sealing system. Moreover, gasket manufacturers will usually have custom kits developed to meet unique requirements for washer-type components.

How can one fabricate custom plastic gaskets?

There are many foreign terms used when discussing custom plastic gasket fabrication, including material selection, cutting techniques, and design. Most suppliers carry large stocks of plastic gasket sheet material, which they convert into many different shapes. Using CAD software can provide design data for precise dimensions and machining. From the design data, the desired gasket shape and thickness can be rendered using die-cutting or CNC machining. Through these fabrication methods, a large selection of custom gaskets can be designed to suit a particular application for effective sealing and insulation.

What are the advantages of using plastic seals over traditional gasket materials?

Plastic seals have their advantages over conventional materials, especially with regard to environmentally resistant and durable properties. They resist chemicals and can stand up to heat. That could make them very useful in various applications. Moreover, plastic seals are much lighter than steel ones, thus they may come in handy where being capable of lowering the weight of a whole system is desired. Good sealing and insulation capabilities with plastic seals eliminate the possibility of leakage in the system and help in establishing its integrity. In addition, plastic seals are manufactured across extensive thickness ranges, hence giving better opportunities for precise adaptation to any specific application.