Depending on the application, the decision to choose between metal gaskets and rubber gaskets is critical as sealing directly affects functionality, safety, and maintenance. Both materials have their pros and cons; therefore, the final selection is always subject to the application. This article, therefore, analyzes and provides an extensive comparison of metal and rubber gaskets with respect to their properties, work life, and temperature limitations while suggesting uses for them. By the end of this discourse, you will have enough inputs to contribute an informed viewpoint on which gasket will be best suited for your particular application.

Understanding Gasket Materials

Material or type of gasket will be selected depending on what performance or seal it has to perform in working conditions. Metal gaskets are excellent in resisting deformation and, therefore, used in industrial applications where extraordinary pressures and temperatures are involved-the petrochemical, power generation, and aircraft industries, to name a few. Rubber gaskets are characterized by excellent flexibility, resilience, and sealing performance under conditions of relatively low to moderate temperature and pressure. They offer the best option where chemical compatibility and vibration dampening are in concern, e.g., automotive, plumbing, general manufacturing, etc. Hence factors like temperature, pressure, chemical exposure, abrasive nature of the application, etc., go into considering an appropriate gasket material to ensure the best performance and reliability.

What are Gaskets?

Gaskets are mechanical seals designed to fill the space between two or more mating surfaces, thereby preventing leakage of fluid, gas, or contaminants under operating conditions. Generally, gaskets are made of materials such as rubber, metal, cork, or synthetic composites of which each can withstand pressure, temperature, and chemical exposure to a certain degree. They are critical towards ensuring tight and reliable sealing in automotive, aerospace, construction, and manufacturing industries. By filling variations on mating surfaces, gaskets ensure interlock integrity and safe operation of the equipment or systems they serve.

Types of Gasket Materials

Types of gaskets are determined, depending upon working conditions, temperature, pressure, and chemical resistance. Closest examples of gasket materials are:

- Rubber Gaskets: Used generally for such reasons as flexibility and chemical resistance, rubber gaskets (neoprene, nitrile, and EPDM) are used in sealing installations where elasticity and toughness are a priority. They find wide application within the plumbing and automotive and HVAC industries.

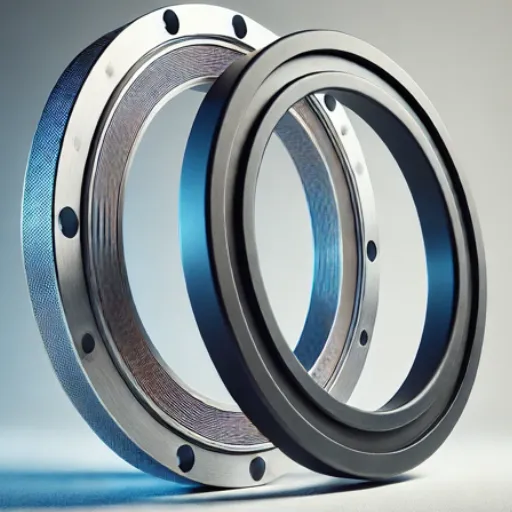

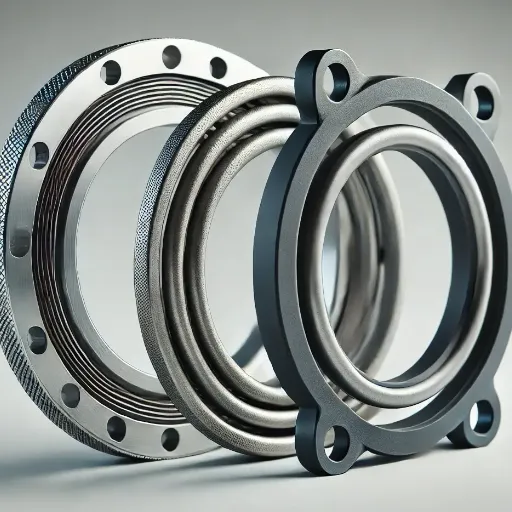

- Metal Gaskets: With metal gaskets (steel, copper, aluminum), high-pressure and high-temperature conditions are created (engines and industrial equipment). Spiral wound, solid metal gaskets give strength and durability even under harsh conditions.

- Compressed Fiber: These gaskets, being prepared from synthetic fiber and elastomers, can be used to seal under conditions of moderate pressure and temperature. Their use goes a lot in the petrochemical and marine industries.

Once the engineers select a particular gasket material, the gasket material assures optimum performance, durability, and safe application across a wide spectrum of industrial activities.

Overview of Rubber and Metal Gaskets

Rubber and metal gaskets with their sealing technologies represent those conflicting properties inflicted upon each other, meant for various used cases. Rubber gaskets made of materials such as EPDM, Nitrile, or Viton become highly flexible systems that provide perfect sealing in low to moderate temperature-pressure environments, giving specifications of their usage in plumbing, HVAC, and industrial chemical-processing systems. Metal gaskets, however, covering spiral-wound and ring-type joint (RTJ) designs, are usually the thought for high pressure and high temperature conditions as are quite common in oil and gas and industrial power systems. Their respect towards integrity and deformation make them exceedingly appropriate for essential sealing requirements in no less-demanding environments. Thus an appreciation of the peculiarities of both types allows engineers to meet operational needs in a very informed manner.

Rubber Gaskets: Comprehensive Analysis

Advantages and Disadvantages of Rubber Gaskets

Advantages

- Flexibility and Elasticity: The rubber gaskets present fine elasticity and can be flexible in shapes, bending on irregular surfaces to provide sealing.

- Resilience to Vibration: In vibrations, these gaskets absorb opposing control shocks, practically reducing bad stress on a joint and its connections.

- Chemical Resistance: Rubber gaskets are able to resist chemical attacks, oil attack, and temperature effect, depending on the type of rubber (e.g., nitrile, EPDM, or Viton).

- Cost-Effectiveness: Rubber gaskets are generally cheaper compared to metal alternatives and easy to manufacture in various sizes and shapes.

Disadvantages

- Temperature Limitations: Rubber gaskets have a generally lower heat resistance than do metallic or composite gaskets, and so they can hardly be used for high-temperature applications.

- Aging and Degradation: Rubber might gradually lose its property due to UV, ozone, or frequent thermal cycling, thereby imposing a negative impact on performance.

- Compression Set: Some rubber mixtures become deprived of their elasticity after extended compression, which further hampers their ability to act as a proper seal.

- Limited Structural Strength: Rubber gaskets lack such rigidity and strength that might be required in a high-pressure application handled mostly by metallic or reinforced gaskets.

Key Benefits of Rubber Gaskets

- Flexibility and Conformity: Rubber gaskets provide excellent flexibility to mold over irregular surfaces and create a dependable seal when the flange surface is not perfectly smooth or flat.

- Chemical Resistance: The rubber materials such as EPDM or nitrile are very resistant to chemicals, oils, and solvents, thus apt for many industries and applications.

- Temperature Tolerance: Based on the rubber compound used, rubber gaskets allow temperatures from very low to moderately high, thus applicable for both low temperatures and moderate high temperatures.

- Cost-Effectiveness: Rubber gaskets, when compared with their metallic counterparts, are generally cheaper and easier to manufacture, thus a very economic solution to many applications.

- Vibration and Noise Dampening: Owing to the elastic properties of rubber, these gaskets can absorb vibrations and dampen noise transmission, enhancing the equipment performance and life span.

- Ease of Installation: Being lightweight, rubber gaskets occupy less manpower and installation time; any required adjustment during the assembly processes is very minimal.

Limitations of Rubber Gaskets

Rubber gaskets even with this strength will have several limitations to be taken into consideration. These limitations arise, such as old-aged degradation caused by extreme temperature, UV radiation, certain chemicals-harden, cracking, and swelling. In addition, rubber gaskets can be limited in high-pressure refutation, wherein alternative materials would be considered, such as metallic or composite gaskets. Thus, this compressibility will act against the loss of shape or sealing effectiveness when compression is put on for a long period or at repeated intervals. One can see why it is essential to look at the precise operating conditions before opting for rubber gaskets during any critical application.

Applications of Rubber Gaskets

Rubber gaskets find applications across numerous industries owing to their versatility and advantages. In the automotive domain, they are used to seal in engines, transmissions, and other applications to prevent fluid and gas leaks. In plumbing might also be a popular choice, whereas in HVAC, the gaskets create seals in pipes, valves, and ductwork under varying temperature and pressure conditions. Rubber gaskets are of utmost importance in the aerospace and electronics industries owing to their vibration resistance, dust, and moisture proof capabilities, enabling optimum functioning of complex assemblies. They are all the more versatile when they can conform to custom shapes and sizes, thus making rubber gaskets extremely useful in both normal and specialized sealing applications.

Metal Gaskets: Comprehensive Analysis

Advantages and Disadvantages of Metal Gaskets

Advantages

- Durability: Metal gaskets, In consequence of better strength and longer durability, are considered suitable for high pressure, high temperature sealing applications.

- Thermal Resistance: They are capable of performing their sealing function even under extreme temperature conditions, thereby supporting their use in more demanding applications such as engines and turbines.

- Chemical Compatibility: Due to their resistance to chemical destruction, metal gaskets have retained their functionality in corrosive environments.

- Reusability: Some metal gaskets can be reused in certain designs and applications, thereby providing a cost advantage.

Disadvantages

- Cost: Usually, metal gaskets will be more costly to manufacture than their non-metallic counterparts.

- Installation Complexity: These seals might be difficult to handle during installation due to them requiring very precise installation and bolt tension for maximum sealing effect. This can also affect the assembly procedure.

- Unsatisfactory When Surfaces Are Not Flat: If the mating surfaces are irregular or damaged, then metal gaskets probably won’t seal well.

- Less Flexibility: Rubber or composite gaskets being inherently flexible can perform better in applications with movement or vibration.

Benefits of Metal Seals

Maintenance of ability under demanding conditions and corrosion prevention and weathering are perhaps the factors from an innumerable list that provide the metal seals with their innumerable advantages. Unlike non-metallic seals, metal seals keep their ability and shape under a very harsh set of working conditions namely, high pressure, or violently corrosive environments. The fact that they cannot afford even a little leakage makes them extremely well-suited to long-term use. Metal seals can operate competently in an extraordinary range of temperatures, thereby ensuring their operation even under cryogenic as well as high-heat environments. Therefore, they find several applications in aerospace, automotives, and energy sectors where reliability and precision take precedence.

Limitations of Metal Gaskets

With their specific actions that offer superlative performance in some of the most demanding applications, metal gaskets do present a few constraints. First, metal gaskets’ sealing action requires very high clamping forces that may require enhanced bolting or flange systems. Second, they are less forgiving of imperfections on the mating surfaces when compared to soft gasket materials; thus, surface finish and flatness become absolutely critical in ensuring a good seal. Third, in some environments, corrosion of metal gaskets may become an issue if the material of construction is not selected carefully, relative to operating conditions. Finally, another downside to metal gaskets is their price, which can make them more expensive to fabricate when compared to non-metallic ones; and such price increases can in certain instances be a limitation for cost-conscious applications.

Applications of Metal Gaskets

Metal gaskets find application in areas where extreme temperature, pressure, and chemical resistance is needed. Commonly, they find use in the oil and gas, petrochemical, power generation, and aerospace industries. These gaskets seal high-pressure pipelines, flanged connections, and critical equipment like heat exchangers and pressure vessels, ensuring their integrity under thermal cycling and harsh environments relevant for demanding processes. Furthermore, metal gaskets will be found in cryogenic and, in fact, environments with aggressive media where non-metallic materials are apt to fail. Their durability and accuracy keep them in favor for procedures that demand stringent safety, as well as efficiency criteria.

Selection Guide and Best Practices

Choosing the Right Gasket

When selecting the fitting gasket for an application, a few critical factors must be determined:

- Operating Condition: Determine the temperature, pressure, and media in question; this will help you understand whether the situation calls for a metal, non-metal, or composite gasket.

- Chemical Compatibility: Make sure the gasket shall not react with the fluids or gases involved to ensure degradation will not occur over time.

- Bolting Force and Flanges: Ensure that the chosen gasket will withstand bolting procedures with the flanges without exerting too much force, which may damage either.

- Standards and Certifications: Gaskets to be considered are one that adheres to standards such as the ASME or API to guarantee proper performance for safety and compliance in a regulated market whilst considered.

- Durability and Maintenance: Consider the gasket lifespan and ease of replacement to reduce downtime and operating cost.

Upon taking into consideration the factors above, the ideal gasket for your application should then be selected to provide the greatest performance, reliability, and safety on the task at hand.

Factors to Consider When Choosing a Gasket

In gasket selection, there are specific key aspects that should be analyzed to ensure the right one for your application. It begins with the operating environment about temperature, pressure, or exposure to aggressive chemicals, as these factors govern material compatibility and performance. Confirm that the gasket material resists all thermal and mechanical stresses it would be exposed to and that it can maintain load during operation without deformation or failing. Check whether it is necessary to meet any standards such as those instated by ASME or API to guarantee safety and conformity to regulations. Also, consider its durability and ease of installation, as this affects the maintenance schedules of the factory and overall operational efficiency. These considerations would allow for a more informed choice that would improve system reliability and reduce unexpected downtime.

Comparing Rubber and Metal Gaskets

Rubber gaskets are mostly preferred where flexibility and adaptability to changing surfaces are required and are most effective in low pressure and temperature environments. They are also resistant to chemicals such as oils and solvents and are a very cost-effective solution for most industrial processes. They, however, suffer degradation through exposure to extreme temperatures and prolonged exposure to harsher chemicals.

Metal gaskets, therefore, measure up against all others in terms of durability and viability for high-pressure and temperature conditions. They also surpass others on resistance to thermal expansion and mechanical stress; that is why they find use in oil and gas industries for critical applications. Metal gaskets tend to have much higher upfront cost; however, with the longevity of the product and performance, the answer to whether those factors outweigh the extremes is leaning towards the product longevity of metal gaskets as viable. The actual operational requirements of temperature, pressure, and chemical exposure are assessed in determining the choice specifying rubber- or metal-based gaskets.

How to Choose the Right Gasket Material

Selecting a particular type of gasket material involves making an in-depth evaluation that contemplates the environment of operation with system parameters. Among the essential considerations would be the actual working temperature and pressure ranges, as such are used to determine the most appropriate material that would sustain sealing of the two surfaces without deterioration or deformation. Also somewhat important is chemical compatibility of gasket material with any liquids or gases that would be present in a system to ensure breakdown of usability over time. Compatibility should likewise be high if great movement is expected in the particular system, thereby requiring great flexibility and resilience to maintain excellent sealing. Cost is also a concern, thus a balance between cost, durability, and maintenance level must be evaluated. By lining up these factors with the demands of the application, the most suitable material for the gasket can be chosen, ensuring the efficiency and reliability of the system.

Conclusion and Future Outlook

Conclusion

Selecting the right gasket material must be a careful consideration of temperature resistance, chemical compatibility, mechanical strength, and system dynamics. Consideration of the operating conditions, as well as the compromise between cost and performance, will then offer a proper choice of such a gasket that minimizes risk and guarantees long-term reliability. An in-depth knowledge of the application criteria is an imperative requirement toward preventing failure and may eventually allow for maximum sealing ability.

Final Thoughts on Gasket Selection

Choosing the right gasket is a matter of matching the material properties to the particular requirements of an application. Factors considered are operating temperature, pressure and chemical environment. These affect the working and longevity of a gasket. It should also have mechanical properties, such as compressibility, recovery, and resistance to creep relaxation, that are compatible with those expected from the system in which it is placed. Neglecting or over-focusing on cost will cause either an economical or an inefficient gasket specification. In the end, it is only by working through all of the application parameters combined with accepted standards and practices that the best option can be afforded for gasket selection.

Future Trends in Gasket Materials

The advanced gasket materials research and development is propelled by the higher performances desired under extreme conditions such as in high temperature, in aggressive chemicals, and in intense pressure. Innovations tend to create materials with maximum durability, flexibility, and eco-compliance, including non-asbestos compositions or environmentally friendly manufacturing methods. Further material science progress also translates into the development of composite gaskets that offer the best engineering properties from different materials for optimum sealing performance. In addition, future trends indicate that new paint and surface treatments will be introduced to reduce friction, improve sealing capabilities, and make the gaskets more long-lasting. The recent developments in digital technologies such as predictive modelling and smart materials will further shape gasket performance, enabling real-time monitoring for industrial applications and allowing for proactive maintenance.

References

-

DXT Seals – The Pros and Cons of Using Rubber vs. Metal Gaskets: This article discusses the advantages and disadvantages of both rubber and metal gaskets in industrial settings.

-

DP Seals – Rubber vs Metal Seals: A detailed comparison of rubber and metal seals, focusing on cost, shock resistance, and flexibility.

-

LinkedIn Article by Prabhat Industries LLC – Choosing the Right Gasket Material: Rubber vs Metal: Highlights the strengths of metal gaskets in extreme conditions and the flexibility and chemical compatibility of rubber gaskets.

- Top Metal Gaskets Suppliers in China

Frequently Asked Questions (FAQs)

What are the advantages and disadvantages of rubber gaskets compared to metal gaskets?

Rubber gaskets perform well in flexible sealing solutions. They are ideal in applications where movement or vibration happens. They tend to be relatively cheap and can handle moderate ranges of temperature; however, they are unsuitable for extreme environments. On the contrary, metal gaskets are generally unsurpassed for durability, withstanding extreme temperatures and high pressures. Factors to consider when deciding between rubber or metal gaskets include your specific application, the type of fluid being sealed and those environmental factors. Metal gaskets usually perform well in high-end applications, while rubber gaskets are used for the average ones.

How do rubber and metal gaskets differ in terms of sealing material properties?

The sealing material properties of rubber and metal gaskets are greatly different. Here, rubber gaskets, preferably of natural rubber and nitrile butadiene rubber (NBR), are elastomers prima facie offering flexibility and compression recovery. Hence, they seal well under variable pressure forces. In contrast, metal gaskets are rigid and durable under conditions offering good temperature ratings meant for applications with high temperature and extreme conditions. Considering the advantages and disadvantages, it is important to reflect on how either of the materials suits the sealing solutions needed for your respective project.

What is the right gasket material for high-performance applications?

Since metal gaskets are capable of withstanding high extreme temperatures and pressures, they are generally the right gasket material to choose in terms of sealing solutions meant for high-performance applications. Compared to rubber gaskets, they offer the best in durability and resistance, whereas rubber gaskets might break down under harsh operating conditions. Rubber gaskets could be considered where flexibility is a big consequence to the application. To make the best choice regarding gasket material, one must evaluate the requirements of their application in relation to the substances being sealed and the mechanical stresses involved.

How can I choose the right gasket for my application?

The type of gasket you select should depend heavily on the factors that concern your application, such as fluid types, temperatures, and pressure ratings. In the extreme cases, metal gaskets would far outlast those of rubber in terms of durability and resistance. For cases where flexibility and a decent seal are needed at relatively low pressure, rubber would take the badge. Another thing you should look into is the cost, the ease of installation, as well as whether the gasket will wear out with time. Consider using a manufacturer’s technical support to help you decide.