For your piping system, occasionally the choice narrows to a slip-on and a socket-weld flange. Both commonly find application in industrial setups and, yet, are majorly different in design, installation process, and performance under various conditions. This blog is meant to shed light on the welding differences between slip on and socket weld flanges, so that you can see how each uniquely fits its particular application. Whether you are well-employed and have had several experiences concerning these, or this is your first foray into these choices, the following comparison provides you with the material for an informed decision.

Understanding Flanges

The flange is a vital component used for coupling pipes, valves, pumps, or any other equipment in a piping system. They provide strength and flexibility along with an option for any cleaning or inspection or modifications. The common types of flanges that are used include slip-on and socket weld flanges; the applications for these differ. Slip-on flange is slipped into the pipe and welded to it. This flange is easy to install and low-cost. The socket weld flange is made with a recess in which the pipe ends are held prior to welding. This weld makes the joint stronger and leak-proof. The flange to be used depends on the system pressure, temperature, and performance factor.

Definition of Flanges

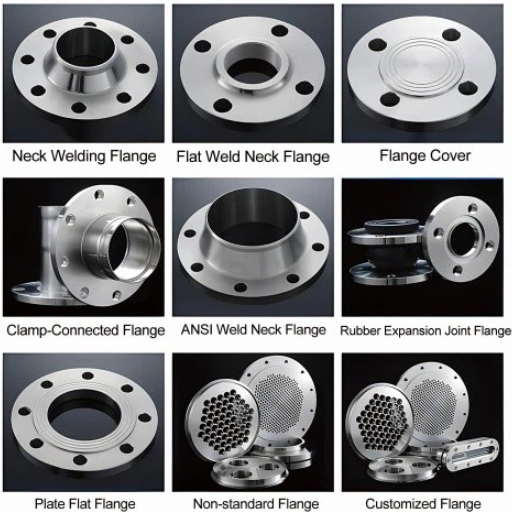

They are flanges and are one of the most important subassemblies in piping systems, capable of joining pipes with valves, pumps, and other equipment, thereby providing a secure, leak-proof seal. They also provide access for inspection, cleaning, or modifications. The flange is extremely diverse and is categorized according to its general design and utility. Popular kinds include slip-on, socket weld, blind, threaded, and lap joint, each being suitable for certain applications. Slip-ons are cheap and fast to install, whereas socket weld ones ensure better joint strength. Blind ones seal the ends of pipes, threaded ones ideally operate at low pressures, whereas lap joint ones allow for the rotational alignment of the flange – making it a good choice when a system is going to be dismantled frequently. In choosing the correct flange, pressing rating, temperature condition, and material compatibility of the system are some of the significant parameters. This then guarantees the reliability of the system, along with the safety and efficiency of the operations.

Types of Flanges

|

Type |

Pressure |

Size |

Use |

Key Feature |

|---|---|---|---|---|

|

Weld Neck |

High |

All |

High-pressure systems |

Stress-resistant |

|

Slip-On |

Low |

All |

Easy installation |

Cost-effective |

|

Socket Weld |

Medium |

Small |

High-pressure pipes |

Compact design |

|

Lap Joint |

Low |

All |

Frequent disassembly |

Reusable |

|

Threaded |

Low |

Small |

No welding needed |

Quick install |

|

Blind |

Very High |

All |

Sealing pipe ends |

Strong closure |

Importance of Flange Selection

Making the correct flange choice is extremely crucial as it directly influences the safety, durability, and operational efficiency of a piping system. The correct flange should provide proper sealing, preventing any possibility of leakage, and it should be capable of standing against system pressure. In this consideration, temperature tolerance, corrosion resistance, and material compatibility come into play so that a system failure accompanied with repair costs does not occur. Also, an incorrectly chosen type of flange will complicate assembly/maintenance/alignment and could lead to decreased operation performance and greater downtime. When choosing a flange, a knowledgeable choice will consider all aspects to satisfy existing standards and overall operations reasonably better in reliability.

Slip-On Flanges

When slip-on flanges are employed in piping systems, the installation procedure is so simple and inexpensive that they become a popular option. These flanges, designed to slide over the pipe, are welded inside and outside to strengthen the joint and avoid leakage. They are suitable for very-low-pressure applications, where alignment flexibility is essential, because the system is often subject to adjustments. For these flanges, compatibility with various materials is ensured, empowering a range of industries. To choose a slip-on flange, one must learn how to determine system requirements in relation to pressure ratings, temperature ranges, etc., so that the slip-on flange can be fully compatible for use.

Construction and Design

While building and designing slip-on flanges, I consider practicality and adaptability. These flanges are simply designed with low profile in order to slip over the pipe before being welded into place, ensuring a secure connection and being leak-free. They are manufactured in a variety of materials, such as stainless steel, carbon steel, and alloys, according to the requirements of various industries. I take into account the considerations of system pressure and temperature, compatibility with piping material, and conformity to standards such as ASME or ANSI when choosing the appropriate slip-on flange so that it can be used under different working conditions reliably while maintaining structural integrity and efficiency.

Welding Methods for Slip-On Flanges

Two kinds of welds I generally employ to make the connection secure and leak-proof while fitting slip-on flanges onto a pipe. Generally, the first weld is a fillet-weld along the inside corner seam where the pipe meets the flange. This weld gives a strong base and does not allow any kind of gap to form for drops to leak across. The second weld is applied over the outside of the pipe-flange interface, reinforcing the joint, thereby gaining even more pressure and structural integrity. Such dual welds are not only above the norms of the industry but also help in hardening the assembly to be wrought in high-pressure and high-temperature operations. Following the correct welding procedures and conforming to the procedure specifications from some major references like ASME codes enables me to provide for my installations’ peak performance and long-term reliability.

Advantages and Disadvantages

Another critical advantage of using dual welds at the interface between pipe and flange lies in the higher strength and reliability it imparts in almost all stringent situations of pressure and temperature. Such systems guarantee more structural integrity and longer life for the joint, with a very low chance of joint failure occurring. Likewise, the acceptance of the design-based specifications under the ASME Code gives extra assurance of safety and quality. On the other hand, the disadvantage includes the fact that it takes time in its execution, since dual welding requires special skills and proper inspections to ascertain the weld’s effectiveness; hence, the increase in the total cost of the project. Usually, however, the benefits gained in the long term are greater than the capital investment needed.

Socket Weld Flanges

Socket weld flange is a trustworthy choice in small-diameter piping systems where high pressure and strength are required. The flanges are joined by inserting the pipe into the socket of the flange, which is then welded all around at the outside, thus making a strong, leak-proof joint. The main advantage of the socket weld flange lies in the fact that the recess dug into it helps in reducing any turbulence and erosion that could occur from high-pressure applications. They also provide simplicity for alignment during installation, ensuring a proper connection. However, it is generally recommended for pipes of diameter 1½ inches or less and might require considerations if they were to be used in corrosive environments for long-term performance.

Construction and Design

Socket weld flanges are interrupted by a recessed area to hold the pipe for accurate welding, bearing in mind a sure connection. Such a design offers a smooth flow, thereby avoiding any potential turbulence or erosion within the system. Pipe insertion into the socket is followed by welding around the circumference of the outer edge, ensuring a tight and practically leak-proof seal. This design is good for smaller sizes, usually 1½ inches or under, and for high-pressure purposes. Material choice is also of great importance in corrosive environments, wherein the alternative of a more durable or resistant material might warrant its best performance and lifetime.

Welding Techniques for Socket Weld Flanges

Precision is all-important since safety and durability could be compromised under high pressure during welding of socket weld flanges. Fillet welds are among the most common types, as they provide a strong joint from welding on the outside edge of the pipe and flange. The real preparation starts by cleaning the pipes and flanges so that they don’t have any oil, grease, or oxide dirt, all of which can weaken a weld.

Meanwhile, an appropriate gap between the pipe and the socket shoulder should be ensured prior to welding. This gap is usually 1/16 of an inch to allow for thermal expansion during operation and to prevent cracking. Such advanced methods as TIG and MIG welding are often used for precision and high-quality welds. TIG welding is called for especially when increased strength and decreased porosity are important. Weld choice, however, may be dependent on materials, application, and environmental conditions.

The recent trend in welding has been the use of automated processes and testing integrity, including pipelines, with radiographic or ultrasonic tests to assess the welds on socket weld connections. This is to ensure the socket weld system is repeatable and leak-resistant in demanding fields such as petrochemical, power generation, etc. Grading of socket welds using these advanced techniques enables optimization for better performance and longer operational life.

Advantages and Disadvantages

Advantages

Socket welds provide many advantages, which is handy for applications requiring stronger connections and complete leakage-proofess. Foremost, a socket weld is much stronger than other types of welds due to the fillet welds, ideal for piping systems under high pressure. During welding, there is no opportunity for misalignment; thus, the weld will be precise and thus strong during fits. A real plus about socket welds is that with their fit, they can technically provide a complete sealing, so leakage is less likely to happen, which is very important for industries such as petrochemical and power generation. Moreover, the simple process of installation results in fewer mistakes compared to other welding methods.

Disadvantages

However, the socket weld carries certain limitations. Mainly, the gap formed between the pipe and the socket during welding serves as a crevice, becoming susceptible to crevice corrosion, especially in corrosive environments. This instigates potential long-term maintenance problems. The fillets for socket welds, being welds, might not be easy to inspect for weld defects after installation. One might do with advanced inspection methods such as radiographic or ultrasonic testing, thereby increasing the costs. Their use is mostly limited to smaller-diameter piping, thus limiting its wider applicability compared to other welding processes.

In essence, it is the foregoing advantages and disadvantages that magnify the need for good planning and operating condition evaluation to ensure the successful working of and long life for socket weld systems.

Comparing Slip On vs Socket Weld Flanges

| Parameter | Slip-On | Socket Weld |

|---|---|---|

| Pressure | Low/Moderate | High |

| Strength | Moderate | High |

| Installation | Easy | Precise |

| Cost | Low | High |

| Pipe Size | Large | Small |

| Leakage | Moderate Risk | Leak-Proof |

| Material | Carbon/Alloy Steel | High-Strength Steel |

| Usage | General Systems | Critical Systems |

Socket Weld Flange vs Slip-On Flange

When comparing socket weld and slip-on flanges, the choice depends greatly on the type of application. Socket weld flanges are used in small-diameter piping systems where strength and leak resistance are required. They offer the most secure connection under high pressure and high temperature due to the pipe being fillet welded at the end. Moreover, socket weld flanges have excellent fatigue resistance, hence are used on systems with cyclic stress.

Slip-on flanges may suit more versatile water supply systems, whereas operations that are not so strenuous in high-pressure remain best for slip-on flanges.

Slip-on flanges are a type of flange that is slipped over the pipe and welded both internally as well as externally, hence giving strength to the assembly and making it easier to install, so less labor is required when compared to socket weld flanges. Such flanges may not sustain pressure or thermal fluctuations, limiting their use in demanding industrial conditions.

Yet another corroboration from recent search trends says that socket weld flanges meet an increasing demand in oil and gas, chemical process industries owing to their reliability when applied under stringent conditions, whereas slip-on flanges find a layman application on construction and low-pressure systems due to their cheapness and simplicity.

Basically, the decision should be made upon considering pressure ratings, material grade, budget constraints, and the operational requirements, so that there’s an ideal balance of performance and cost-effectiveness.

Welding Differences Between the Two

The fundamental difference in these two flanges is found in their welding procedures and application techniques. Socket weld flanges are attached by inserting the pipe into the flange’s socket and then applying a single fillet weld that runs the entire circumference of the flange. The weld thus made is capable of withstanding the demands of high-pressure service. Slip-on flanges need the pipe’s pass through the flange before welding it inside and outside the flange. The structural strength is less than for socket weld flanges, but facilitates an easy alignment during installation. Therefore, socket weld flanges are used for critical systems having stringent safety requirements, whereas slip-on systems mostly find themselves placed along systems of low pressure but with cost constraints.

Applications and Use Cases

Since socket-weld flanges offer robust connections, they are mainly used under high-pressure conditions like hydraulics, steam lines, and chemical processing plants, where the need for reliability is paramount. Additionally, they are most suitable for situations wherein vibration or stress might prove destructive, ensuring the fit is retained and the risk of leaking is reduced. Slip-on flanges, on the other hand, find wider applications under low pressures such as water distribution, Heating, Ventilation, and Air Conditioning systems, or low-temperature pipelines. They are cheaper due to installation convenience and easy alignment for applications where systems are considered non-critical, but Rapid installation and versatility rank top priority.

Conclusion

If I may, let me clarify that my choice of flange would very much depend on the particular use and requirements. In cases of high-pressure or high-stress applications, a welded type of flange must be chosen for safe installation since it involves durability considerations. In other systems, in which the pressures are low, or they are non-critical applications wherein speedy installation or lower cost takes precedence, I would rather put a slip-on flange.

Summary of Key Differences

Depending on the application requirements or operating conditions, one might prefer a weld-type flange rather than a slip-on flange, or vice versa. Welded flanges are stronger, tougher, and resistant to higher pressures and stresses and thus fit the higher elevations. Slip-on flanges are quick to assemble and cheaper, but are used for pressure lines or less critical applications. Either way, the decision should be based on a compromise of performance, cost, and ease of installation.

Final Recommendations

Depending on the processing requirements and budget, one may be able to decide on the weld or slip-on flange. Welded flanges, by virtue of being stronger and more durable, are suited for high-pressure and high-stress environments. Slip-on flanges are more suitable for low-pressure systems and those applications where cost and time of installation are considered paramount. Such a decision will have to be dependent on the particularities of the system to get the best balance between performance, cost, and ease of installation.

References

- Visual Encyclopedia of Chemical Engineering

This source provides an overview of different flange types, including slip-on and socket weld flanges.

Link to source - Take Offs For Socket Weld Fittings (Johns Hopkins University)

A detailed PDF resource discussing socket weld fittings and their applications, including comparisons with slip-on flanges.

Link to source - Piping Code Comparison (U.S. Department of Energy)

A report comparing piping codes, including details on slip-on and socket weld flanges.

Link to source - Top Socket Weld Flanges Suppliers in China

Frequently Asked Questions (FAQ)

What are the main differences between slip on flanges and socket weld flanges?

Slip on flanges and socket weld flanges differ primarily in their design and installation methods. A slip on flange is designed to slip over the end of a pipe, which makes it easy to align and weld. In contrast, a socket weld flange fits over the pipe and requires a fillet weld around the joint. This results in a more secure joint, ideal for applications involving higher pressure. Additionally, slip on flanges are generally used in lower pressure systems, while socket weld flanges are commonly preferred in high-pressure applications.

What is the significance of the flange face in socket weld flanges?

The flange face plays a crucial role in ensuring a proper seal between two flanges. For socket weld flanges, the raised face design helps to improve the sealing capability, preventing leaks under internal pressure. A well-maintained flange face is essential to avoid damage during installation and operation. If the flange face is not correctly aligned or is damaged, it can lead to significant issues, including leaks or even failure of the system. Therefore, ensuring the integrity of the flange face is vital for both slip on and socket weld flanges.

How do welding techniques affect the performance of slip on and socket weld flanges?

Welding techniques significantly impact the performance of both slip on and socket weld flanges. Socket weld flanges typically require one fillet weld, which enhances their static strength and fatigue strength, making them suitable for high-pressure systems. On the other hand, slip on flanges may require more attention during installation to ensure the weld is secure. The choice of welding heat and technique can also affect the integrity of the joint, especially in high-temperature applications. Proper welding techniques ensure longevity and reliability in both types of flanges.

Are there specific applications where socket weld flanges are preferred over slip on flanges?

Yes, socket weld flanges are often preferred in applications that involve high-pressure systems and smaller-diameter pipes. Their design allows for a secure joint, making them ideal for pressure vessels and piping systems that experience high internal pressure. Moreover, socket weld flanges are typically used in areas where space is limited, making them an efficient choice for compact installations. Conversely, slip on flanges are more suitable for low-pressure applications and larger pipe sizes, where ease of installation is prioritized over joint strength.

How do the costs compare between slip on flanges and socket weld flanges?

Generally, slip on flanges are less expensive than socket weld flanges due to their simpler design and installation process. However, the total cost can vary based on the material and the specific application requirements. Socket weld flanges, while slightly more expensive, offer better strength and reliability, particularly in high-pressure situations. When considering costs, it’s essential to factor in not only the initial purchase price but also the long-term benefits and potential savings from reduced maintenance and failure risks in critical applications.