Selecting the appropriate flange type for piping systems means the difference between operating smoothly and suffering costly delays. There are numerous types of flanges, but lap joint and slip-on are perhaps the most versatile, each meant for specific applications and design features. So how does one know when to use which? This guide details the characteristics, positive aspects, and applications of lap joint and slip-on flanges, while also touching on the weld neck for longevity and performance. Whether you are an engineer, a contractor, or just curious, this article provides the best foundation for making the right choices. Read on to know the details that make or break the next-level piping systems.

Understanding Flange Types

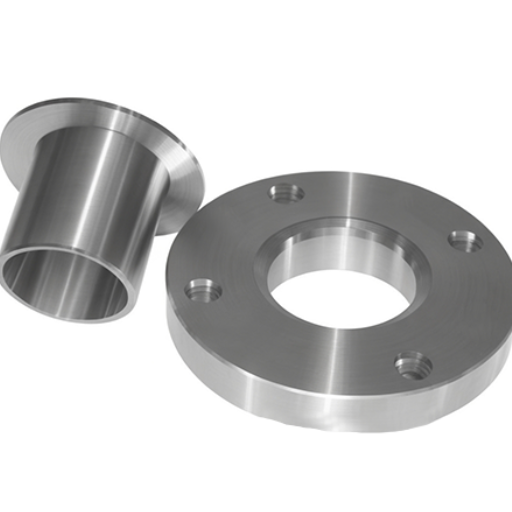

Flanges form the essential parts in piping systems used for interconnecting pipes, valves, pumps, and other equipment. The three primary types of flanges include lap joint, slip-on, and weld neck flanges:

Lap Joint Flanges: These flanges are used in situations where disassembly should occur frequently and are commonly used with a stub end. They help developers align their flanges accurately and are much cheaper in cases where the pipe is not exposed to a very high pressure.

Slip-On Flanges: These flanges are placed over the pipe and welded in position. These flanges are easy to fit and remain cheap for consideration in low-pressure systems.

Weld Neck Flanges: These flanges being more durable, are mounted with a welding process that strengthens the flange and makes it resistant to stress. So, those flange types are marked for pressure and temperature systems.

Consideration of pressure, temperature, and potential of assembly or disassembly decides the flange type.

What is a Flange?

A flange is a mechanical entity that helps connect pipes, valves, pumps, or any other piece of equipment to generate a secure and efficient system. Generally, the flanges are circular and exhibit rows of bolt holes, which guarantee a tight, leak-proof joint when bolted onto a matching flange. Their main function ensures the integrity of piping systems so that in industries like oil and gas, chemical processing, and water treatment, liquids, and gases may be safely transported.

There are many different types of flanges, each intended for specific applications, including slip-on, weld neck, blind, threaded, and lap joint flanges. Choosing the material, size, and design for a flange depends on whether pressure, temperature, or the nature of fluid or gas to be carried is taken into consideration. Their versatility ensures that flanges are vital, both in high-pressure systems that require brute might, as well as low-pressure applications, where the key is ease of maintenance. With engineering and manufacturing at its best, the flange has been upgraded to meet today’s demand for reliability, adaptability, and precision.

Types of Flanges

|

Type |

Pressure |

Size |

Use |

|---|---|---|---|

|

Weld Neck |

High |

All |

High-pressure systems |

|

Slip-On |

Low |

All |

Easy installation |

|

Socket Weld |

Medium |

Small |

High-pressure pipes |

|

Lap Joint |

Low |

All |

Frequent disassembly |

|

Threaded |

Low |

Small |

No welding required |

|

Blind |

Very High |

All |

Sealing pipe ends |

Importance of Flange Selection

Selection of the appropriate flange plays a critical role in keeping industrial systems safe, efficient, and long-lasting. Flanges are the major points of connection in pipelines, and a wrongly chosen flange can result in delays at costly downtime caused by leaks or even system failures. One must consider very keenly on material compatibility, pressure ratings, temperature on usage, and accurate dimensional measurements. For example: high-pressure environments require stronger flanges, such as those made of stainless steel, while corrosive environments may require special coatings or alloy materials such as titanium.

Recent studies further reveal that industries are pivoting toward precision engine, lightweight flange designs, energy-efficient, and cost-saving solutions, in line with the growing trend for greener alternatives. Likewise, making reference to flange standards, such as ASME B16.5 or EN 1092-1, ensures good compatibility and reliability in global operations, hence the need to follow all industry standards. Simply put, flange selection is way beyond a technical necessity; it is a strategic choice that hugely affects system performance and safety.

Lap Joint Flange

A lap joint flange is a piping flange intended to be used with a stub end or a similar fitting. It finds its common usage in systems that require frequent disassembly or where there may be alignment adjustments. The flange is not welded to the pipe, allowing flexibility and very easy installation. This type of flange finds applications where there is minimal stress on the piping system and is very much useful in systems made of expensive or exotic materials-the stub end alone needs to be made to match the pipe material.

Definition and Characteristics

The ease of use and adaptability of the lap joint flanges make them preferred particularly in systems requiring the frequent removal of equipment for maintenance or inspection. As recent data reveals, a large chunk of online searches deals with the benefits of this type of flange, giving rise to its popularity in industries like petrochemical, food processing, and wastewater management. The distinguishing feature of the lap joint flange is that it can freely rotate about the pipe, thus enabling alignment of the bolts during installation. This ultimately reduces stress on the piping system at large and makes it preferable where precision is of essence. Also, matching the flange with a stub end saves on costs associated with using expensive materials, as the flange metal does not have to be of the same grade as that of the pipe.

Advantages of Lap Joint Flanges

Lap joint flanges have some other advantages that make them highly adaptable to many applications in industrial environments. Their ease of installation and alignment was a big one. Since the flange can be rotated around the pipe to achieve the correct alignment of the bolts, the installation becomes freer, requiring less time and labor. The freedom to make quick changes proves especially useful for engineers working in tight confine or difficult piping systems.

An added benefit comes with an option for stub-end processing. Lap joint flanges partnered with a highly resistant stub end with cheaper material for the flange can dramatically save in costs while still maintaining performance in severe conditions. Moreover, the forgettable benefits stand on their own, mainly in environments where continuous disassembly or maintenance is needed because they ease the reassembling and dismantling procedures.

According to recent facts gathered from varied industry sources, lap joint flanges are increasingly becoming the preference in applications such as chemical processing, oil and gas, and water treatment facilities. The resisting properties against corrosion, adaptability, and economical benefits in specific scenarios are contributing to this trend, thereby lifting it higher in for demand in modern-day engineering and manufacturing projects.

Applications of Lap Joint Flanges

The lap joint flanges enjoy wide usage in several industries, thanks to their unique design and practical benefits. According to the recent data, chemical processing, oil and gas pipelines, and water treatment are among the types of places where frequent inspection and maintenance are required. They resist corrosion in applications where aggressive chemicals and high moisture levels are involved. Since, in these industries, rapid assembly and disassembly lend keen importance to the lynchpin of operational efficiency within the piping system, lap joint flanges are favored.

There has been a swift rise in awareness about lap joint flanges through search trends in renewable energy projects such as geothermal and offshore wind installations, where utmost value is placed on reliability and durability. These flanges may be paired with stub-end fittings for economic savings, optimizing costs without compromising on performance in high-pressure or corrosive environments. The ever-widening versatility confirms the place of lap joint flanges in engineering solutions today.

Slip-On Flange

A slip-on flange is designed to slide on a pipe; it requires welding on the inside as well as on the outside to render a solid connection. Being easy to install, it goes well with the pipe, thus making it a much cheaper and convenient option for low pressure. These kinds of flanges would be suitable, for instance, in systems where space constraints or speedy assembly are given preference, where even less demanding performances are adequate.

Definition and Characteristics

Slip-on flanges are essentially simple in design; a flange slides over the pipe to ensure alignment, then butt welded or fillet welded. Inexpensive and flexible, they are another favorite for systems working under low-pressure and moderate-temperature conditions. A slip-on flange is commonly welded on both sides to provide a secure connection, hence ensuring durability and resistance against leakage. Their easy installation and ability to be fitted in limited-space-area systems make them highly accommodating where space is limited or rapid assembly is necessary.

Advantages of Slip-On Flanges

Amongst other advantages, slip-on flanges are considered advantageous for several reasons, making them preferred in several industries. To begin with, these are an affordable type of flange because their design is quite simple and they use a smaller quantity of material in their manufacturing. Next, this type of flange offers an installation process that is truly simple, not requiring too much precision or effort, and this ultimately saves plenty of time and labor costs. At times, these flanges are welded inside and outside, creating extra security against leaks. This guarantees slip-on flanges can be fitted well in systems running both in high and low pressure.

Recent records also highlight their versatility in several industrial applications. Slip-on flanges are widely used in piping systems that transport water, steam, and other non-aggressive fluids. Due to their low profile and compact design, they also prove to be better suited for tighter spaces or designs that leave limited room for complicated connections. This versatility in handling carbon steel pipe, stainless steel pipe, or alloy pipes further increases their usability to cater to different demands from industries in chemical processing, HVAC systems, and oil and gas refineries. All said and done, these combined advantages make slip-on flanges one of the most trusted and preferred choices engineers make when weighing cost factor against performance.

Applications of Slip-On Flanges

Because of their versatile capabilities and ease of installation, slip-on flanges are applied extensively across different industries. They are used in chemical processing plants for handling pipelines in transporting reactive materials, due to their capability to accommodate different pipe materials and diameters. Slip-on flanges are also frequently installed for HVAC systems to secure connections within heating, ventilation, and air conditioning networks. Moreover, the oil and gas industry leverages their reliable performance in connecting pipelines involved in the transportation and processing of crude oil and natural gas. Slip-on flanges are a good solution for systems that require a dependable connection with varying pressure and temperature conditions due to their adaptability and cost-efficiency.

Lap Joint Flange vs Slip-On Flange

|

Parameter |

Lap Joint |

Slip-On |

|---|---|---|

|

Design |

Two-piece |

Single-piece |

|

Installation |

Flexible |

Simple |

|

Cost |

Higher upfront |

Lower upfront |

|

Maintenance |

Easy access |

Limited access |

|

Pressure |

Medium |

Low to medium |

|

Applications |

Frequent disassembly |

Permanent setups |

|

Alignment |

Adjustable |

Fixed |

|

Size |

Large pipes |

Small/medium pipes |

Key Differences

Below are several major points of contrast between a lap joint flange and a slip-on flange that decide their respective uses and their criteria for specification. A lap joint flange works in tandem with a stub end and provides mobility and ease to systems whose laying needs to be changed quite often. This makes it perfect for those kinds of systems where maintenance or alignment is to be carried out from time to time; the flange assembly can thus be taken apart without any need for further cutting or welding.

Slip-on flanges, conversely, are welded directly to the pipe and thus form a permanent connection. They are cost-effective for simple installation, especially for low-pressure or non-critical systems. These flanges need to be welded in two places for their complete securing, which adds strength rather demanding process from welders, unlike lap joint assembly.

From the perspective of compatibility, the lap joint type is mainly used where the systems have varying materials for pipe and flange, as the design of the lap joint minimizes materials’ stresses and corrosion at the connection points. The slip-on flange style takes versatile action in straightforward settings for long-term stability and cost-effectiveness. Both types serve their distinct purposes: industries can, therefore, balance functionality with cost-efficiency as need be.

When to Use Lap Joint Flange

Lap joint flanges are used when a piping system needs frequent disassembly-assembly activities conflicting with simultaneous adjustments since slight rotation on the lap to stub end joint is permitted without creating stress in the pipe. They benefit greatly from situations where different materials are used as pipe and flange because their design mitigates the chance of galvanic corrosion or devaluation of such materials. They are used commonly where cost savings is a primary concern, especially in low-pressure applications or when expensive, exotic materials are specified, making them usable for very specialized and maintenance-intensive environments.

When to Use Slip-On Flange

Slip-on flange is the best choice where ease of installation and cost-effective considerations come into play. Slip-ons are well suited to low-pressure applications, lookup operational demands being moderate, with less risk of leakage. Slip-on flanges provide the advantage wherever periodic maintenance or replacement is to be carried out, for their welding method is simpler and the alignment procedure uncomplicated. They are also well suited for non-critical applications or when more economical or specialized materials are employed. The versatility and practicality have earned the slip-on their widespread utilization in many industries.

Weld Neck Flanges

Weld neck flanges are intended for high-pressure and high-temperature applications. The long, tapered boss provided for maximum reinforcement and stress concentration on the flange, ensuring long-standing reliability and durability. These flanges find their use predominantly in the oil and gas industry, chemical processing plants, and power generation areas where safe and secure connections are of utmost necessity. The design of these flanges prevents any chance of leaks that would otherwise be suitable for very critical systems requiring stringent performances.

What is a Weld Neck Flange?

A weld neck flange is a kind of flange with a long, tapered hub that facilitates the smooth transmission of stresses in the attachment to a pipe. This design lends itself favorably to installations for dealing with high pressure, high temperature, or both. The flange itself is weld-connected to the pipe so as to create a permanent connection that assures very good strength and resistance to mechanical stress.

The type is used quite widely in critical industries, such as oil and gas, petrochemical, and power generation. Due to their strong nature, pressure is kept to the lowest degree of leaks, even under operating extremes. These flanges can be fabricated in austenitic carbon steel, stainless steel, alloy steel, etc., so that they can be applied in systems and environments that are quite broad. Weld neck flanges, thanks to their topmost performance and longevity, are a must for pipelines, pressure vessels, and other devices that require secure and long-lasting connections.

Comparison with Lap Joint and Slip-On Flanges

There are, therefore, a few key differences when one compares weld neck flanges with lap joint and slip-on flanges. In terms of high-pressure and high-temperature environments, weld neck flanges are most useful owing to their seamless connection, thus proving the best for those critical applications, while lap joint flanges are for applications where systems have to be disassembled often or systems have to be aligned, thus offering flexibility to be taken off. On the other hand, slip-on flanges are the easiest to install and the cheapest but usually not as durable as the weld neck flange during extreme usage conditions. All the flanges have their advantages but it largely depends on the individual needs for a specific application and system requirements.

Applications of Weld Neck Flanges

Weld neck flanges have an absolutely immense demand in applications that require resistance to high pressure and temperature and integrity of structure. They are operating an act in such industries as oil and gas, power generation, and chemical processing where performance is an imperative requirement for pipelines, heat exchangers, and critical systems. Superior leak prevention is ensured through these flanges in harsh environments, and these delayed operations of transporting hazardous or pressurized fluids and other high-stress operations guarantee their suitability. Other than these operations, it’s their serious ‘build quality’ and ‘functionality’ that help them stand in shipbuilding, nuclear plants, and high-pressure testing systems as center points and cement their status as the very first choice in critical industrial applications.

References

- Michigan State University: A detailed PDF discussing bolted connections and their applications, including slip-critical joints. Link to source1.

- University of California, Davis: A comprehensive document on advanced topics in steel design, covering various joint types, including lap joints. Link to source2.

- Office of Scientific and Technical Information (OSTI): A resource discussing lap-joint flange slip connections and their role in differential settling. Link to source

- Top Lap Joint Flange Suppliers in China

Frequently Asked Questions (FAQ)

What is the difference between lap joint flanges and slip-on flanges?

Lap joint flanges and slip-on flanges are two distinct flange types, each with unique applications. A lap joint flange is designed to fit over a lap joint stub end, allowing for easy alignment and removal. In contrast, a slip-on flange slides over the end of a pipe, providing a simpler installation process. While lap joint flanges offer greater flexibility in assembly, slip-on flanges are often preferred for their straightforward design. Both flanges can be welded to the pipe using a fillet weld, but the choice between them often depends on the specific requirements of the piping system.

How do lap joints and slip-on flanges compare in terms of installation?

When comparing the installation of lap joints and slip-on flanges, slip-on flanges are generally easier to work with. A slip-on flange simply needs to be slipped over the end of a pipe and then welded, making it a popular choice for many applications. On the other hand, lap joint flanges require the use of a stub end, which can complicate the installation process slightly. However, lap joint flanges shine in situations where frequent disassembly is necessary, as they allow for easier access compared to slip-on flanges. Ultimately, the choice will depend on factors such as the piping layout and the need for maintenance.

What are the common dimensions of lap joint flanges and slip-on flanges?

Common dimensions for both lap joint flanges and slip-on flanges vary based on the standards they adhere to, such as ANSI or ASME. Flanges are manufactured in various sizes, typically ranging from ½ inch to 24 inches in diameter, with different flange thicknesses depending on the application. Lap joint flanges are often paired with specific lap joint stub ends, which must match in size for proper installation. Slip-on flanges, on the other hand, can also be found in reducing sizes, known as slip-on reducing flanges, to accommodate different pipe diameters. It is crucial to ensure that the dimensions match the corresponding pipe or fitting to prevent any damage to the flange face.

Are lap joint flanges and slip-on flanges suitable for high-pressure applications?

Both lap joint flanges and slip-on flanges can be suitable for high-pressure applications, but their effectiveness can depend on the specific conditions. Lap joint flanges are often preferred in applications that require frequent disassembly, as they minimize the risk of damage to the flange face during removal. Conversely, slip-on flanges are generally simpler but may not perform as well under extreme pressure without proper welding techniques. In high-pressure scenarios, it’s essential to consider the material and quality of the flanges, as high-quality steel flanges can withstand greater stress. Ultimately, the decision should be based on the engineering requirements of the specific installation.

Can lap joint flanges be used with blind flanges?

Yes, lap joint flanges can be effectively used in conjunction with blind flanges. A blind flange is designed to close off the end of a piping system, and when paired with a lap joint flange, it provides a versatile solution for pipe connections. The lap joint flange can facilitate easier removal and maintenance, while the blind flange ensures that the system remains sealed when needed. This combination is particularly useful in systems that require occasional access for inspection or repairs. However, it is important to ensure that the flange dimensions and types are compatible for optimal performance.