Lap joint flanges in piping systems are indeed highly versatile and easy to install. This article investigates the two main components of a lap joint flange and how they combine to achieve effective and reliable connections in various system applications. By identifying the main components, the reader can get an insight into their design, function, and the benefits offered to systems where disassembly or adjustments need to occur on a frequent basis. Regardless of whether you are constructing a new system or maintaining one, this guide will walk you through the basic knowledge of lap joint flanges and their main features.

Understanding Lap Joint Flanges

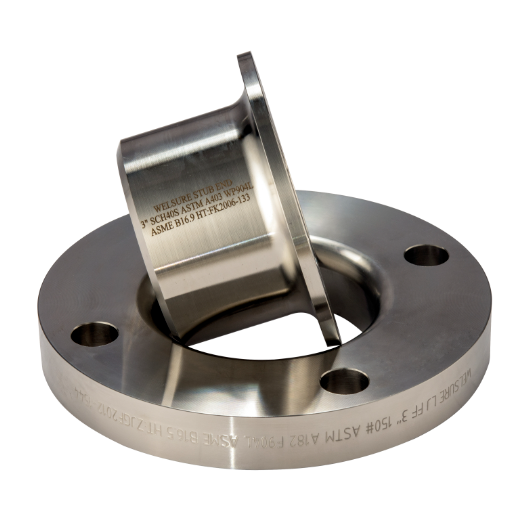

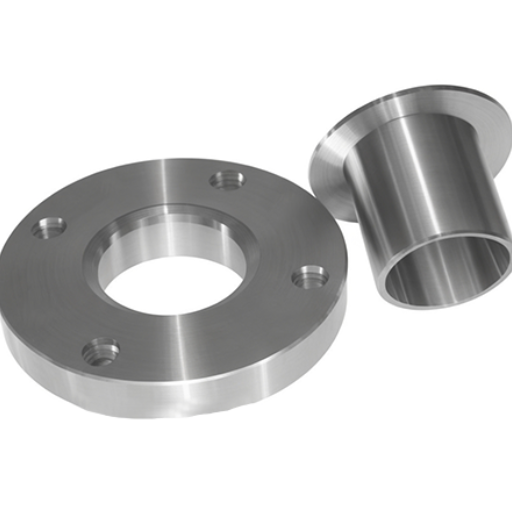

In their design and application, they are quite unique and consist of the two components, namely, the stub end and the flange ring. The stub end is welded to the pipe, while the flange ring fits loosely over it and allows for quick alignment and adjustment. With this design, lap joint flanges are especially suitable where systems require assembly, disassembly, or realignment on a regular basis since they reduce wear on flange faces and make the process easier. Because the flange ring is not made from the same material as the pipe, they are also a more affordable option when it comes to low-pressure, non-critical applications.

Definition and Purpose

Lap joint flanges are a class of flanges intended to mate with the stub end. They offer great flexibility and easy usage. The main reason for utilizing these flanges is to simplify the assembly and maintenance of piping systems, especially those wherein disassembly may be frequently required. Due to costs and their effect on the reduction of wear of an expensive material, these flanges find greater application in non-critical, low-pressure applications. They further assist in installation alignment by allowing the flange ring itself to turn.

Components of a Lap Joint Flange

Lap joint flanges consist of two main components, namely, the stub end and the backing flange. The stub end is a short piece of pipe with a flange face welded or machined to the end of the pipe that fits closely against the backing flange. The backing flange is the loose piece that can rotate around the stub end during the installation for easy alignment. This design offers flexibility, reduces stress on the piping system, and promotes reusability; therefore, making it a practical choice in various applications. The components join together elegantly to ease assembly and improve efficiency in a system.

Differences Between Lap Joint and Other Flange Types

Comparing lap joint flanges against other flange types presents just a few key differences. The first and foremost difference is the fact that lap joint flange is actually a two-piece flange consisting of a stub end and a backing flange that come in between for easier alignment and more flexibility during installation, as opposed to other flanges like weld neck or slip-on, which are single-piece flanges requiring precise alignment and welding.

Secondly, the difference is in reuse. If systems require frequent disassembly or inspection, lap joint flanges suit best since the backing flange can be reused even if the stub ends may have to be replaced. Other flanges, such as socket-weld or threaded flanges, don’t have that level of adaptability as they involve mostly permanent connections.

Lastly, lap joint flanges, usually, are not as strong as weld neck flanges when it comes to pressure or stress. This, however, does not undermine the fact that they give room to applications where these features become a priority by virtue of their being cost-friendly, easily maintained, and adaptable.

Types of Lap Joints

| Type | Description | Strength | Application |

|---|---|---|---|

| Basic | Simple overlap | Low | Framing |

| Half-lap | Material removed for fit | Medium | Woodworking |

| Mitered | Angled overlap | High | Cabinetry |

| Cross-lap | Mid-board overlap | High | Furniture |

| Dovetail | Decorative “V” | High | Cabinetry |

Stub End and Its Role

In piping systems where frequent disassembly is a necessity, a stub end plays an important role. It serves as a component of lap joint flange which facilitates its installation and removal without welding. Hence, it proves instrumental when maintenance or inspection is involved. By reducing the welding of flanges, it decreases the creation of stress points that could compromise longevity under working conditions of varying environmental stress. Hence, it becomes most versatile and workable, ensuring that this choice is a must in both industrial and special piping projects.

Slip-On Flanges Explained

In any piping system or works, slip-on flanges are practical and popular choices primarily for the reasons of simplicity of installation and low cost. These flanges slide over the pipe, and welding is done both inside and outside the flange to guarantee firm attachment. Very flexible and practical for low-pressure operations where the risk of fluid leakage is minimum, compared to other flange types, slip-on flanges require less precise pipe cutting, making them a favorite choice in sites where emphasis is laid on just getting the job done quickly and simply. Due to their adaptable nature and affordability, they enjoy widespread acceptance across several industries such as oil and gas, chemical processing, and water management systems.

Swivel Flanges and Their Applications

Swivel flanges are versatile components that mainly facilitate alignment during the connection between pipelines or equipment in various industrial sectors. They are made up of two main parts—an outer ring that rotates and a center-type hub, which permits positioning flexibility to guarantee accurate placement. These flanges are especially pertinent in systems that require frequent maintenance or modification, such as offshore, subsea installations, and high-pressure applications. By minimizing both the time and effort for installation, the swivel flange design provides practical solutions to promote operational efficiency and reliability in demanding environments.

Advantages of Lap Joint Flanges

Lap joint flanges render several famed advantages, thereby making them suitable for numerous applications. Firstly, the uniqueness of its design allows easy alignment during installation, which saves labor and assures proper fit in even more complicated systems. Secondly, these flanges are cheap to procure in relation to the type of stub-end fittings; for the flange never is in contact with the internal fluid-softer, less-costly material may be used without sacrificing utility. Thirdly, these are very much appropriate to systems that demand frequent disassembly or inspection because they can be removed and replaced relatively easily compared to other flange types. This plus high adaptability for setting under high pressures or corrosive atmospheres means that lap joint flanges provide operational efficiency as well as long-term value.

Benefits in Piping Systems

Lap joint flanges confer an array of benefits on the latest piping systems, especially in industrial applications where consideration of cost efficiency, durability, and ease of maintenance is paramount. By allowing stub ends to be made from corrosion-resistant materials, they preserve piping systems’ longevity, even when being exposed to a hostile environment, such as what is met in chemical processing plants or offshore drilling sites. Furthermore, their reusability is a huge asset with respect to operating expenses since they can be disassembled and reassembled without incurring damage. Industry insights report that the trends nowadays show that high-pressure operation is adapted better by systems designed with lap joint flanges and that they also seamlessly combine with other components. These flanges fit perfectly with concerns on sustainability regarding material waste and overall system cost, which are in line with the trending emphasis on eco-friendly and efficient engineering solutions.

Ease of Maintenance

Lap joint flanges tend to be preferred whenever inspection, cleaning, or replacements are occurring frequently. Regarding industrial systems, inquiries into the efficiency of maintenance have grown substantially, pointing to the importance placed on reducing downtime. The lap joint flange dominates as it can be assembled and disassembled quickly, thus minimizing the resources and time needed to carry out repairs or adjustments. Moreover, it aligns with piping systems quickly to allow maintenance teams to work with accuracy and with as little difficulty as possible. The ease of use coupled with efficiency would be what meets the demands of the high-functioning industrial operations of today.

Cost-effectiveness

Lap joint flanges are an economical choice for industries that wish to build on operational budgets. Being the main contributing factor to these flanges’ cost-effectiveness, go beyond what others offer in mere cost. Being reusable, unlike others, prone to be totally thrown away due to wear or damage, these flanges usually only see replacement of the stub end, saving so much on material costs in the long run. Moreover, less precision in machining during installation equates to a pretty-cheap initial investment.

After consulting recent and up-to-date insights from the industry, it was found that lap joint flanges can reduce maintenance and replacement costs by 20 to 30 percent compared with fixed flanges in high-pressure piping systems. The change in design has really made the flanges very light, which hugely cuts down shipping and handling costs, particularly for the major operations. Acting in this way by reducing downtime allows for a further reduction in labor costs with increased productivity, thus making these flanges very attractive from an economic viewpoint. The durability, along with the reusability and cost-effective design, makes lap joint flanges a good investment for an industrial system of today.

Choosing the Right Lap Joint Flange

There are several key considerations that govern the choice of lap joint flange:

Material Compatibility – The material of the flange should be compatible with the pipe and the medium-resistant to corrosion or chemical reactions.

Pressure Rating and Temperature Rating – The pressure rating and temperature rating should consider the maximum operating pressure and the maximum operating temperature of the system.

Pipe Size and Fit – The chosen flange must fit exactly to the pipe dimensions to prevent leakage and to ensure proper alignment.

Application Requirements – Will the system occasionally require disassembly? This is a good application for lap joint flanges, which can be easily removed and reused.

Industry Standards – The lap flange should comply with necessary standards (e.g., ASME, ANSI) for safety and compatibility.

By taking into account the above factors, an appropriate lap joint flange can be chosen to improve system performance and reliability.

Factors to Consider

Including latest data and trends while selecting a lap joint flange can help provide deeper insight into making the best choice. Data search shows growing interest in flanges optimized for sustainability and energy efficiency. For example, industries nowadays prioritize materials such as stainless steel and duplex alloys that withstand corrosion and prolong durability, thereby marking their suitability for high-pressure and high-temperature environments.

Further, the trend also supports the growing need for flanges that satisfy stricter environmental regulations. Product compliance, therefore, supports greener operations in chemical plants, refineries, and power stations, in addition to following industry standards such as ASME or ISO.

If you mate these emerging considerations with the traditional ones-ease of installation, compatibility, and cost efficiency- you ensure that the selection will meet both present and future duties. Keeping track of industry changes through reliable sources can reinforce your decision-making to maximize optimized performance under such dynamic applications.

Applications of Lap Joint Flanges

Lap joint flanges enjoy widespread use across various industries, mostly in cases where the frequent disassembly and reassembly of piping systems is necessitated. With its unique design consisting of a loose flange upon which the stub-end can rotate, it comes into its own whenever operational alignment issues arise. Chemical plants, refineries, and power stations constitute typical domains for such use, wherein the system’s efficient maintenance and endurance maturing under varied conditions are paramount.

In their design, the flange itself remains somewhat out of direct exposure, keeping costs down with the use of materials with lesser resistance to corrosion, yet without forfeiting durability. This is why they find favor wherever material selection and cost consideration play equal roles, offshore oil rigs being a good example, together with desalination plants and wastewater treatment sites. Therefore, their flexibility and cost-effectiveness are what continue to spur their usage amid dynamic industries.

Flange Manufacturing Techniques

When it comes to the manufacturing of flanges, we employ a myriad of techniques to meet the greatest expectations in precision and durability. It may be forging, casting, or machining that is performed, depending upon what one is expecting in a particular application. Forging gives the ultimate solution for strength and load-bearing because it promotes the toughness and integrity of the flange structure. Casting, on the other hand, allows one to form rather complicated shapes while keeping the costs low. Machining, on the other hand, helps achieve the highest standards of dimensional accuracy. By the perfect choice of the method of manufacturing, we have succeeded in producing flanges that definitely stand in the level of the standards required by the industries and are of great quality that can with urge be relied upon.

Flange Basics in Piping Systems

Flanges are mechanical components used to connect pipes, valves, pumps, or other components for piping systems. They generally consist of solid metal rings that provide secure and leak-proof joints, yet allow easy access for maintenance, inspection, or modification. Hence, the flanges are installed onto their mating surfaces: pipes, pumps, valves-welded or threaded with bolts and gaskets for sealed joints. Among the vast families of flanges are weld neck, slip-on, lap joint, socket weld, threaded, and blind flange, each meeting some particular requirements given the system pressure, temperature, and application. A proper choice of flanges and their proper installation guarantees a reliable and efficient system.

Flanges and Lap Joint Integration

The integration of flanges with lap joints offers numerous advantages, especially when frequent disassembly or alignment adjustment is required. A lap joint flange is normally used in conjunction with a stub end to provide a loose fit which simplifies assembly and alignment of the components. This becomes very useful in systems where thermal expansion and contraction take place as the joint can allow for some slight shifting without affecting the seal.

flange-and-lap-joint configurations find their use mainly in the petrochemical, food-processing, and power-generating industries due to their versatility and relative cost-effectiveness. Users usually wonder how resistant corrosion setup is, which generally depends on the material of the stub end rather than that of the flange, thereby giving the liberty to customize solutions to environmental conditions. When done correctly, this integration boosts system performance and cuts installation time, which results in greater operational efficiency in the long term.

Importance of Proper Installation

Proper installation of flanges and stub ends is important to consider; together, they serve as the primary variable in the reliability and safety of pipe systems. One of the most important aspects lies in making sure that the alignment and torque specifications during the assembly have been met; not properly aligned induces stress onto the joints that might lead to the formation of leaks or the outright failure of systems. Up to 60% of failures of flange connections are, in fact, due to improper installation, data in some engineering guidelines state, showing the value of correct installation.

Next is surface preparation, which is crucial for the best sealing results. Research indicated the importance of having surfaces in-between the gasket and flange that are clean and free of contaminants to ensure the integrity of the sealing system when under pressure and when facing temperature variations. Today, tools such as precision torque wrenches and tensioners help ensure repeatability throughout the procedures, hence eliminating to a large extent, human error.

Following current standards and guidelines, which include ASME as well as ISO, enforce uniformity and compliance concerning safety policies. With proper training and adherence to these best practices, installations will significantly prolong the lifetime of piping systems, minimize maintenance costs, and increase resistance to environmental stresses or operational stresses.

Common Issues and Solutions

Piping systems, with each set having unique situations and therefore their peculiar challenges. Some examples of constraints faced in this industry in general, along with their solutions:

1. Corrosion and Material Degradation:

Corrosion remains the main cause of failure in piping systems, especially when moisture or chemicals act on the system aggressively in an environment. The danger posed by corrosion can be avoided by choosing corrosion-protected materials, e.g. stainless steel or protective coatings. Regular inspection and installing cathodic protection systems can also be very helpful against corrosion.

2. Leakage and Joint Failures:

Leakage could occur when joints are not properly installed or they’re subjected to extreme conditions and stress, which wear out sealing possibilities and diminish their capacity. The solution depends on the use of quality fittings and ensuring joints are properly tightened with correct torque specifications so they can be reliably pressure tested after installation.

3. Pipe Blockages:

These can be due to any form of debris or sediment or may be as simple as scaling coming in and eventually disturbing the flow, thereby affecting system productivity. The solution here ranges from blood donation-system flushing to installing strainers or filters for chemicals or even mechanical pigging to remove clogs from within.

4. Thermal Expansion & Contraction:

Thermal variation changes metals: Temperature fluctuations will cause pipe expansion or contraction-induced stresses, which could lead to cracking or joint failure with the passage of time. Employing expansion loops or flexible couplings or expansion joints will allow the system to accommodate the movement without becoming damaged.

5. Vibration and Fatigue Stress:

This vibration beyond limits is induced mostly by the presence of machinery nearby or sudden surges in fluid. Hence, supports against vibration, dampers, and proper alignment can save pipes from the infliction of these disturbing forces.

From a combination of an industry best-practice approach and the latter technological advancements coupled with maintenance procedures, these common problems can be perfectly taken care of. The implementation of proactive solutions will not only improve the reliability and safety of piping systems but will also minimize downtime and costs in the long run, paving the way for future success.

Reference Sources

- EPA Document on Flanged Joints

This document provides an overview of flanged joints, including their components and sealing mechanisms.

Link to source - PHMSA Bulletin on Lap-Joint Flanges

This bulletin explains the use of lap-joint flanges in combination with a lap joint stub end, detailing their application and structure.

Link to source - Science.gov on Bolted Flanged Connections

This source discusses bolted flanged connections, including structural details and modeling.

Link to source - Top Lap Joint Flange Suppliers in China

Frequently Asked Questions (FAQs)

What are the advantages of lap joint flanges?

Lap joint flanges provide several benefits in piping systems. They are particularly useful in applications where frequent maintenance is required, as they allow for quick disassembly without disturbing the piping alignment. This is due to the loose backing flange that enables the flange to rotate freely. Additionally, lap joint flanges can accommodate misalignment better than other flange types, making them ideal for complex piping layouts. Their design, which consists of a stub end and a lap joint, ensures that they can be easily installed and removed, providing convenience in various applications.

How do I choose lap joint flanges for my piping system?

Choosing the right lap joint flanges involves understanding the specific requirements of your piping system. First, consider the material compatibility with the fluids being transported, as flanges are available in various materials. Next, evaluate the pressure and temperature ratings to ensure they meet your application needs. It’s also essential to determine the size and type of flange required, as lap joint flanges are often used with a lap joint stub end. Consulting with a flange manufacturing expert can also help you select the best options for your system.

What types of flanges are similar to lap joint flanges?

Flanges similar to lap joint flanges include slip-on flanges and socket weld flanges. Slip-on flanges are easy to install and are often used in low-pressure applications. Socket weld flanges, on the other hand, provide a stronger joint than slip-on designs and are suitable for high-pressure settings. While both types have their advantages, lap joint flanges stand out for their ability to allow the flange to rotate freely, which is beneficial in applications requiring frequent maintenance. Understanding these differences can help in selecting the appropriate flange type for your project.

What are the applications of lap joint flanges in piping systems?

Lap joint flanges are widely used across various industries due to their versatility. They are commonly found in chemical processing, oil and gas, and water treatment facilities. Their design, which consists of a stub end and a lap joint, allows for easy alignment with the mating flange, making them ideal for applications where regular access is required. Additionally, they are often used in systems where thermal expansion might affect alignment. Their ability to accommodate misalignment also makes them suitable for complex piping arrangements, enhancing their application range.

Can a lap joint flange be used in high-pressure applications?

While lap joint flanges are generally favored for low to moderate pressure applications, they can be used in high-pressure environments if properly designed and selected. It is crucial to ensure that the materials and dimensions of the lap joint flange meet the pressure requirements of the system. In high-pressure applications, the backing flange provides additional support, enhancing the overall strength of the joint. However, in extremely high-pressure situations, other flange types, such as weld neck flanges, may be more suitable. Always consult with a piping expert to determine the best flange type for high-pressure applications.